Press Photos

Please note our terms of use governing the use of press images. By downloading images from our media database, you agree to these terms of use:

Press images may only be used for press purposes (print, electronic media, online) and may not be edited. Indicating the picture credits (source: Wacker Chemie AG) is obligatory. Images deleted from the media database may no longer be used in future. If a press image is used, please provide us with a copy or link. In other respects, the following copyright information shall apply: www.wacker.com/disclaimer

Category

Reset perimeterHTEssence® spray dryer

A WACKER employee is filling pure, nature-identical hydroxytyrosol dissolved in water in a spray dryer. Thanks to the controlled production process, HTEssence® is free of allergens and pesticides and does not contain any unwanted byproducts or contaminants

Order photoHTEssence® Lab Powder

Spray-dried nature-identical hydroxytyrosol: The odorless, water-soluble powder HTEssence® is available in great purity and with a defined amount of active ingredient.

Order photoFurnace chamber test - Photo 2

Furnace chamber test: Films made with VAE and SB binders are tested at WACKER’s carpet lab in Burghausen. The tests show that specific VAE-based films are self-extinguishing (Photo 1), while films made with SB burn readily, issuing black smoke (Photo 2). VAE-based binders there-fore allow for formulations that need fewer flame retardant additives

Order photoFurnace chamber test - Photo 1

Furnace chamber test: Films made with VAE and SB binders are tested at WACKER’s carpet lab in Burghausen. The tests show that specific VAE-based films are self-extinguishing (Photo 1), while films made with SB burn readily, issuing black smoke (Photo 2). VAE-based binders there-fore allow for formulations that need fewer flame retardant additives.

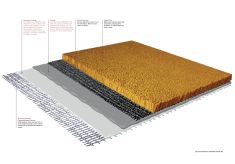

Order photoComposition of a tufted carpet

Composition of a tufted carpet: The new VINNAPAS® CA 55 is suitable for formulating highly-filled precoats which bond carpet fibers to the primary backing. In addition, it also enables the formulation of secondary coatings, which, in turn, bond the carpet to the secondary backing (graphics: Wacker Chemie AG).

Order photo