Producing VINNECO® from Starch

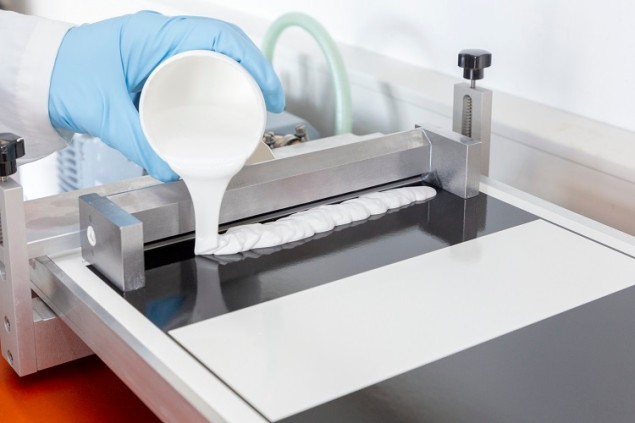

For the second method, WACKER is cooperating with Dynaplak, a Dutch company that manufactures biobased raw materials. Dispersion production in this case is based on starch, which exhibits the properties of a binder when emulsified. This natural polymer is a side-stream product of potato processing. Experts at Dynaplak use this starch, which would otherwise be lost, and modify it with an innovative technology to improve its performance. WACKER combines Dynaplak’s enhanced product with polymers based on vinyl acetate-ethylene to create a new, hybrid binder. The modified biopolymer accounts for 30 percent of the new product. This reduces the amount of traditional VAE derived from fossil-based raw materials by about a third, yielding a lower carbon footprint in the resulting product.

The result is a high-performance binder that WACKER will market under the name VINNECO® CT 7030 which is primarily designed for the production of interior paints. “Our new, hybrid product makes us one of the first companies on the market to combine vinyl acetate-ethylene polymers with starch for industrial applications,” says Dr. Martin Schierhorn, a chemist and marketing manager at WACKER POLYMERS. “We’ve maximized the proportion of starch as much as we can. When it comes to rheological properties, wet-scrub resistance, dispersibility and hiding power, VINNECO® CT 7030 can hold its own with traditional products made from fossil feedstocks.”

As this is a new product with its own property profile, paint manufacturers may need to adapt their formulations. The advantage is that the starch polymer allows them to directly utilize biomass in the finished product. The proportion of biobased material in VINNECO® CT 7030 can be determined with the help of carbon dating.

WACKER will be introducing more VINNECO® products over the course of 2019.

New at ECS 2019: The WACKER Forum

WACKER will be devoting a total of 240 square meters of floor space to solutions for paints, coatings, construction and adhesives applications at the 2019 European Coatings Show. More than 70 experts will be on hand at Booth 1-510 in Hall 1 to discuss the products and their applications with interested parties. Making a new appearance this year will be the WACKER Forum, right beside the main booth. Here, 15-minute presentations aimed at an international specialist audience will be held on technology, trends and innovations under the motto “Let’s talk about...” More information about the program of presentations at the WACKER Forum can be found at www.wacker.com/ECS2019 soon.

About WACKER POLYMERS

WACKER can look back at over 80 years’ experience in the manufacture of polymer binders. Today, WACKER is a leading producer of state-of-the-art binders and polymeric additives based on polyvinyl acetate and vinyl acetate copolymers. These take the form of dispersible polymer powders, dispersions, solid resins, and solutions. The products are used in construction chemicals, paints, surface coatings, adhesives and nonwovens, as well as in fiber composites and polymeric materials based on renewable resources. WACKER operates production sites for polymer binders in Germany, China, South Korea and the USA, as well as a global sales network and technical centers in all major regions.