-

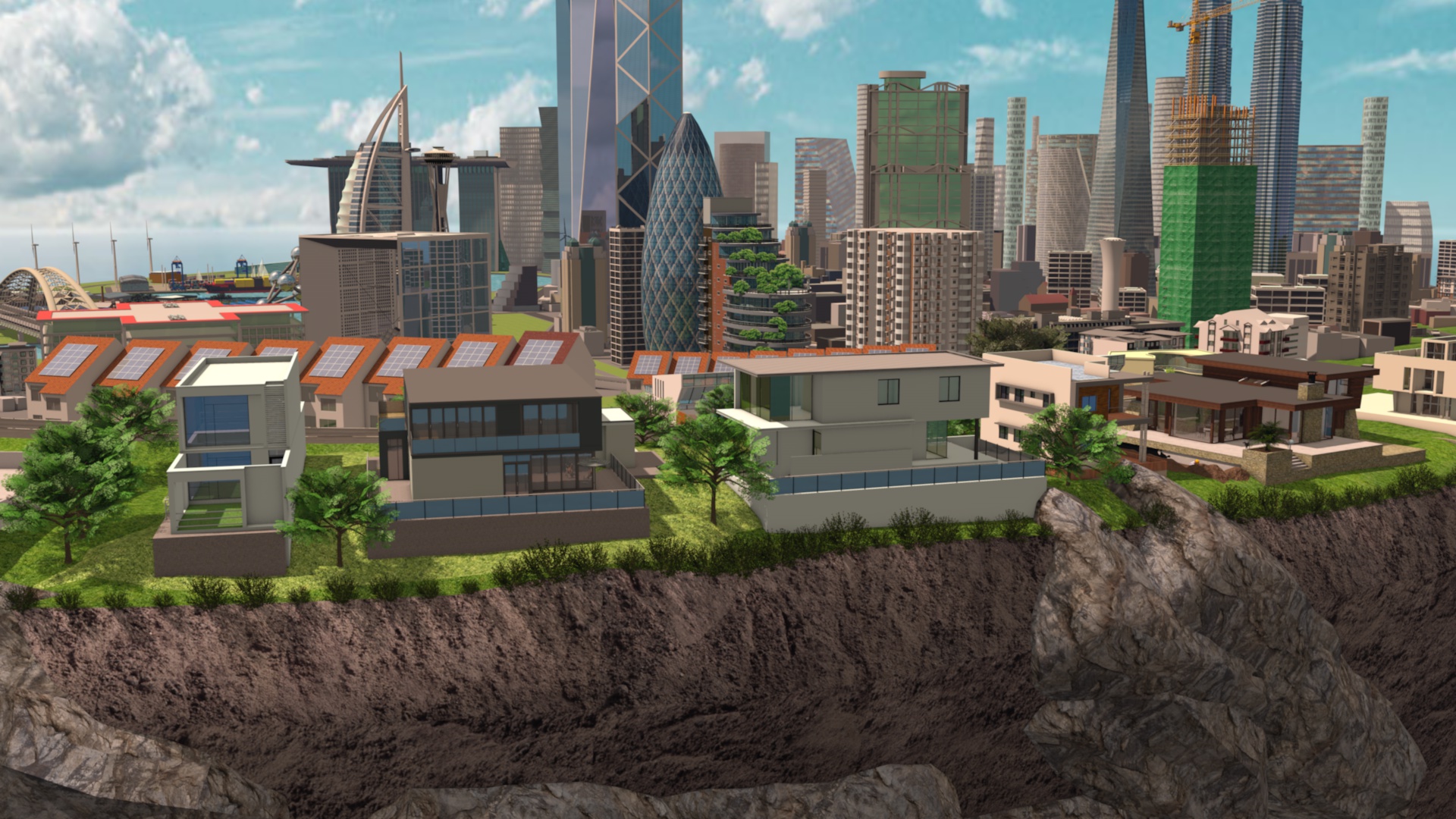

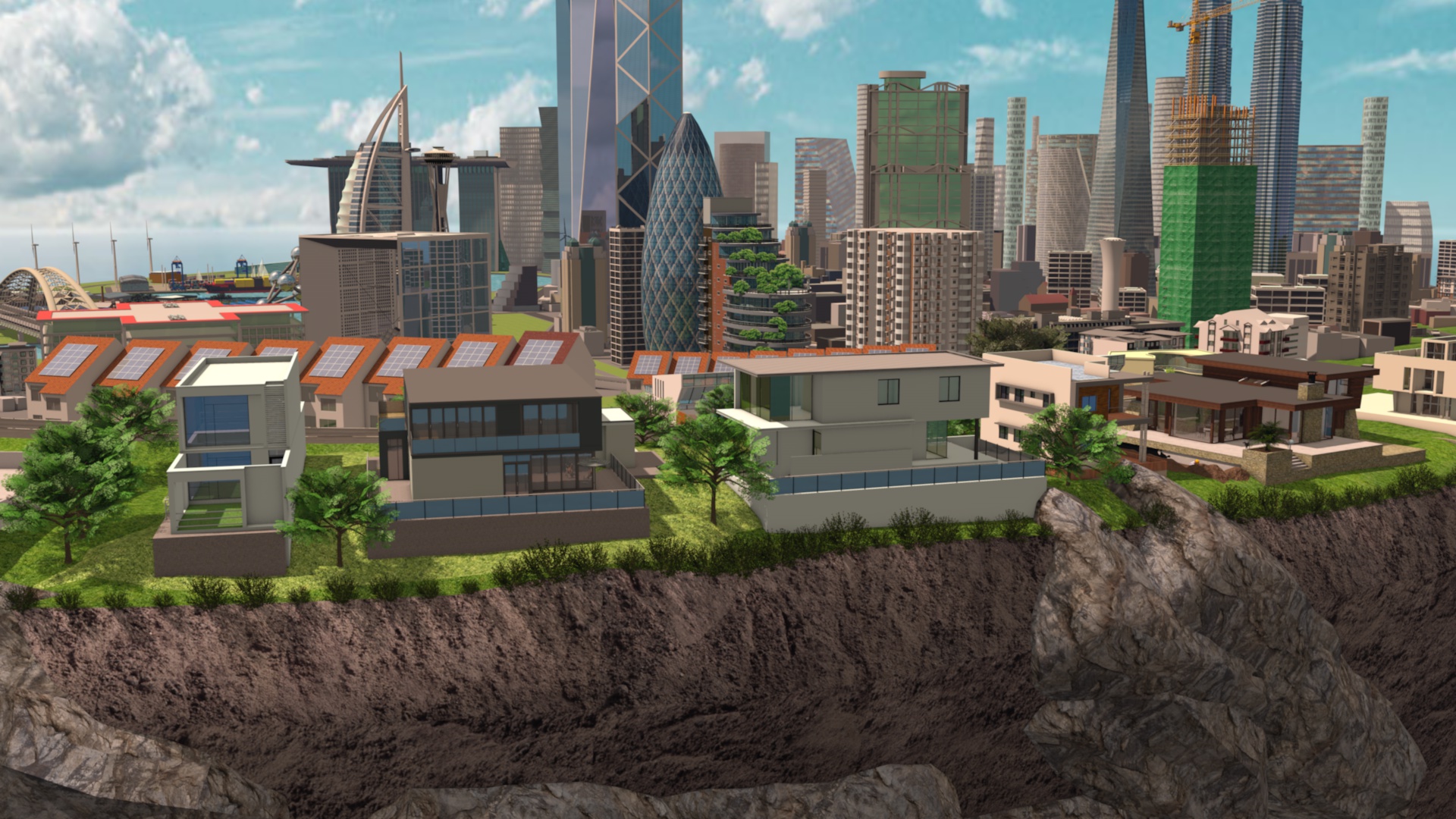

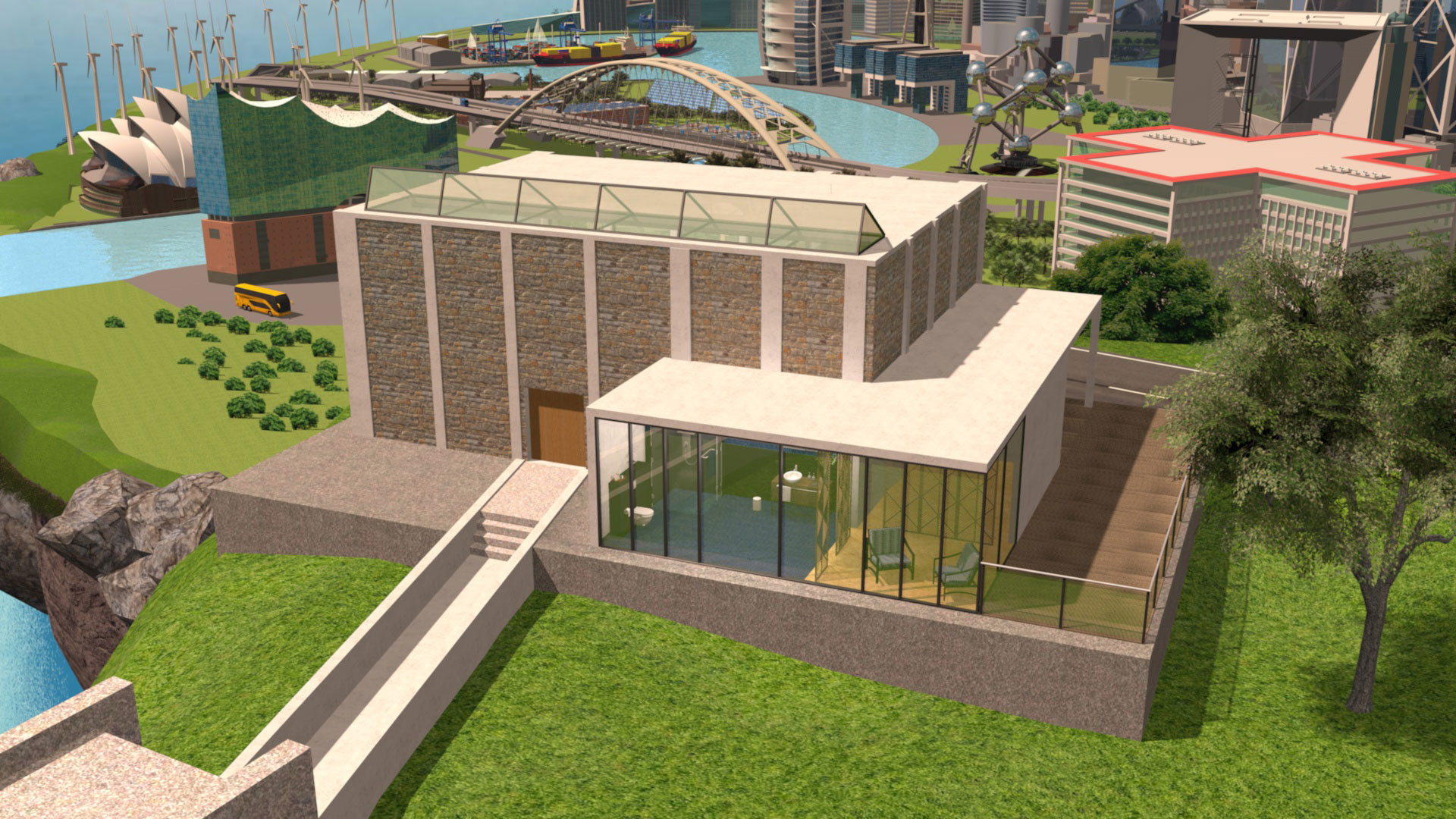

WACKER City

-

Energy

-

Health

-

Construction

-

Household

-

-

-

We began assessing our product portfolio according to sustainable criteria in 2018. To do that, we consider the full life cycle of a product or product group and, in addition to unique regional concerns, pay particular attention to the impact of the application. Along with basic criteria, we also describe the sustainability profile.

You can find a few examples of our sustainable solutions right here in our home town. Simply come in and have a look around.

Corrosion resistant, durable and consistent over the long term: silicone rubber for encapsulating stator slot exits in offshore wind turbines provides outstanding protection – even when exposed to harsh, saltwater conditions – while also serving as electrical insulation.

Multi-use vacuum bags increase efficiency in the production of wind turbine components from fiber composites, reducing manufacturing waste while increasing productivity.

The market for solar panels is growing, as they do more than just reduce CO2 emissions – they save money too. Effective protection from poor weather conditions and UV radiation significantly increases their service life.

The efficiency of solar cells is critically dependent on the quality of the polysilicon used to make them. When it comes to purity, output and quality of service, WACKER is the worldwide market leader.

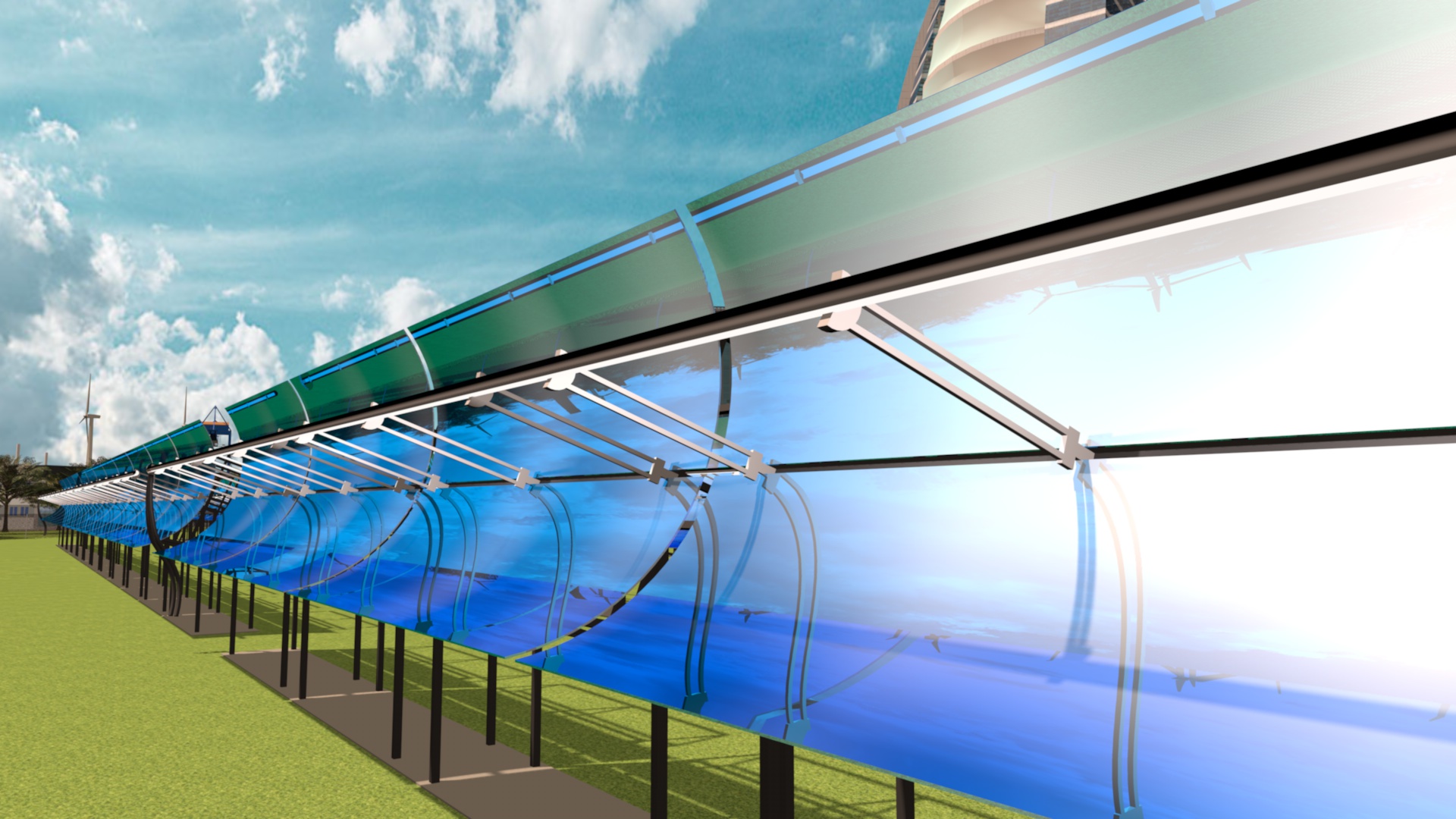

HELISOL® heat-transfer media from WACKER are specially designed to increase the efficiency and cost-effectiveness of concentrating solar power plants. Their exceptional thermal stability and low viscosity reduce the pump energy required, making their use both economical and environmentally friendly.

Sunlight is the key to sustainable energy production. Power plants with parabolic troughs use heat-transfer media to generate electricity or to convert solar energy into environmentally friendly process heat.

Innovative silicone products from WACKER allow automakers to design more efficient motors and extraordinarily reliable components. As a partner to the automotive industry, WACKER is doing its part to shape the future of mobility and helping achieve breakthroughs in alternative drive technologies.

The digital transformation of automobiles is an important factor in more sustainable mobility. Thanks to thermoelastic silicone adhesives, automobile displays can last a long time, even under extreme climatic conditions.

Reliable protection from the elements is crucial for many of the components of vehicles with alternative drives. The requirements are high due to the extreme conditions, such as sudden temperature changes, vibrations or contact with oils and chemicals.

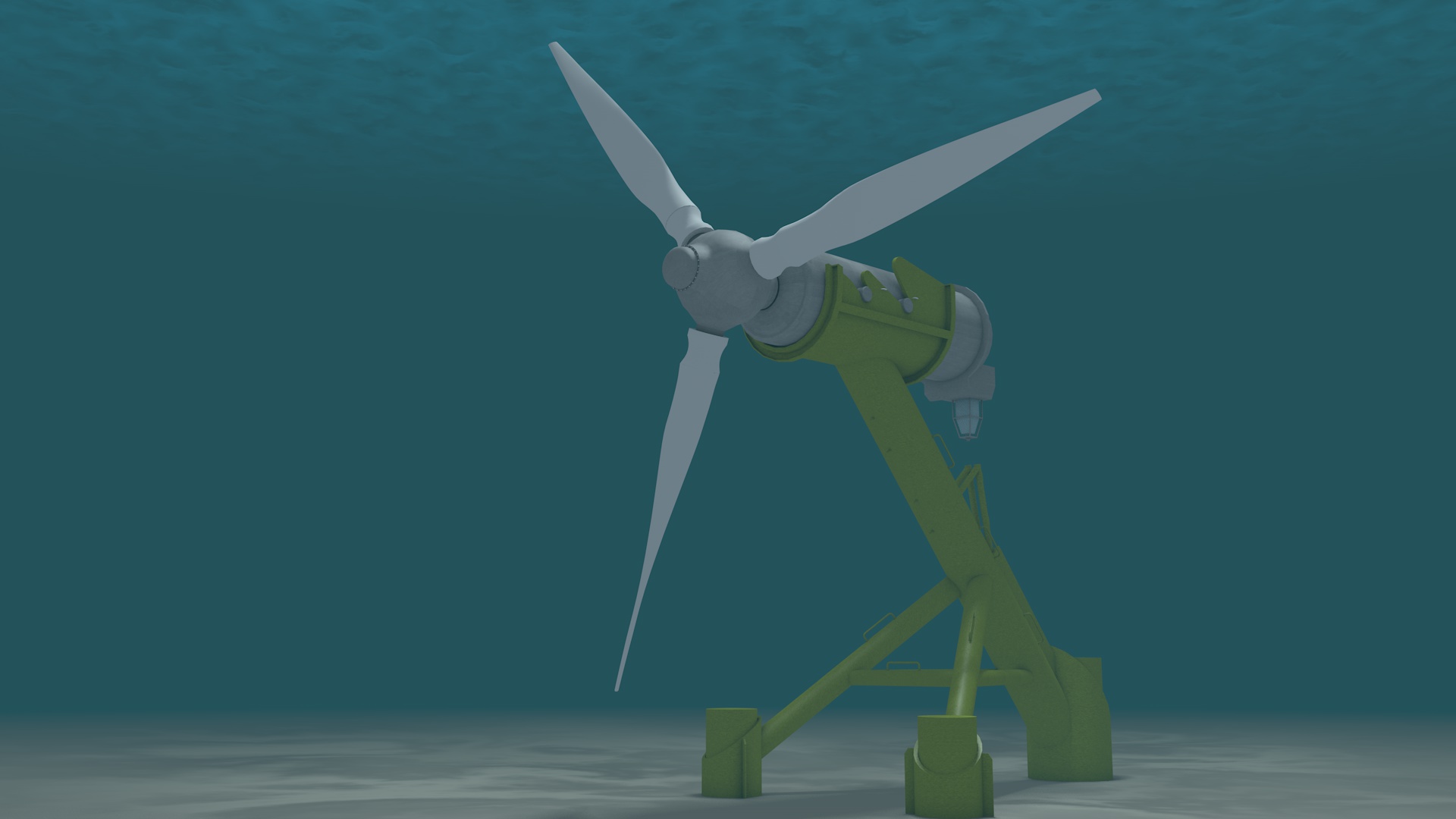

Hydropower generators are essential for the production of renewable energy. WACKER silicone elastomers protect them from vibrations, hold semi-conducting wrapping tapes in place, provide electrical insulation and optimize thermal management.

Non-allergenic, breathable silicone adhesives can be worn longer than standard wound dressings.

Atraumatic removal improves compliance, which leads to faster healing and the use of fewer bandages.

Water is the precious resource of the future. Making clean drinking water available in adequate amounts is critical, especially in hot regions. Cementitious sealing slurries can help, transporting water to where it needs to be without losing a drop.

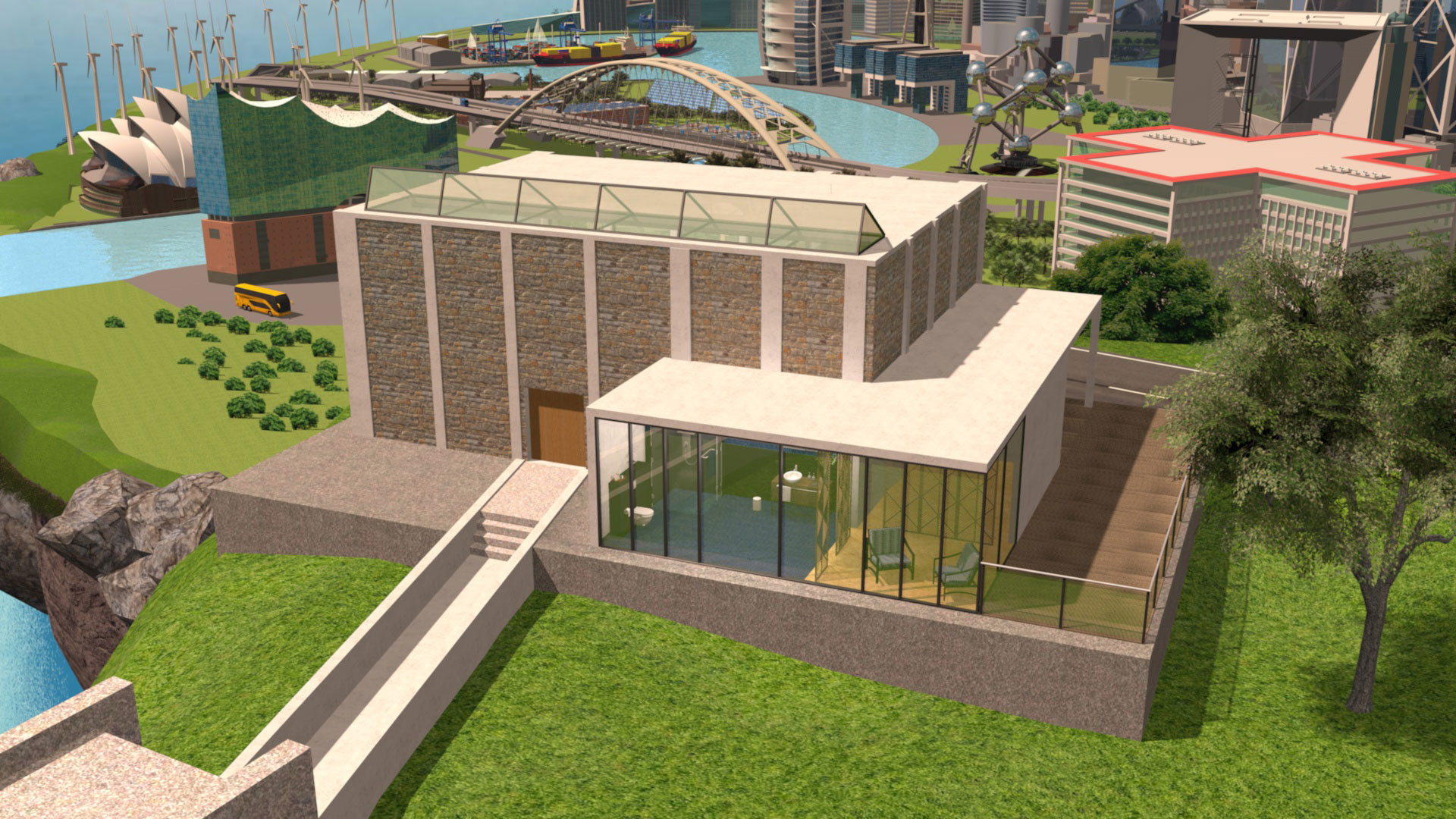

A longer service life without the expensive, time-consuming maintenance and renovation work – WACKER products make exteriors last a long time and improves their energy balance. These facades are also resistant to heat, cold, moisture, UV radiation and dirt.

An exterior thermal insulation composite system, or ETICS, makes a building more energy efficient. If it is to do its job well, an ETICS needs an effective adhesive solution and primer coat for the insulating material in order to make the walls less thermally conductive – an important step on the road to buildings that are climate neutral.

In addition, polymer-modified systems keep the indoor climate healthy, minimizing interior temperature fluctuations in hot and cold climates alike. Dispersible polymer powders allow manufacturers to produce high-quality, long-lasting external thermal insulation composite systems.

While concrete and screed floors are becoming more and more popular, their open-pored structure leaves them very susceptible to dirt. Efficiently preventing stains while allowing water-vapor permeability results in long-lasting floors, saving time and materials.

Steel-frame construction is a staple of modern architecture, offering considerable load-bearing capacity and serving as the backbone of our infrastructure. In order to make steel girders even safer, intumescent coatings are applied to them for extra heat resistance.

Tomorrow’s cities will make effective use of available space and invest in long-lasting infrastructure. Using suitable construction materials for managing water and moisture is a particularly important way of preventing damage and thus conserving raw materials.

Polymer-modified cementitious waterproofing systems play a critical role in keeping moisture from penetrating the building fabric.

As either a topcoat or as a substrate for paintwork or wallpaper, skim coats lend walls a smooth surface structure. When polymeric binders are added to these coats, they become particularly resistant to mechanical stress and moisture, making them longer lasting and thus more sustainable than traditional finishing plasters.

Wood is a renewable building material containing sequestered CO2. When obtained properly, it offers an ideal foundation for a holistic, sustainable economic system. Adhesives are essential for various wood-on-wood applications, where they significantly extend a product’s useful life.

Consumers are constantly looking for furniture made from natural materials like wood, and our dispersions are one solution for producing high-quality furnishings with very low VOC levels.

Wood is an extremely versatile building material. As a natural, renewable raw material, it plays a considerable role in a good indoor climate. Film coatings make wood even more adaptable and extend its life more than paper laminates can.

Most of the sustainable technologies on which our future depends would be impossible without semiconductor materials. Their exceptional purity and extremely low metal contamination make our products a crucial material for the semiconductor industry.

The purpose of insulation materials is to minimize the loss of heat or cold. Vacuum insulation panels with an HDK® core are ahead of the game: they are fire resistant, retain their shape and provide excellent long-term insulation. They also do an especially good job of increasing the efficiency of cold-storage rooms and refrigeration devices and greatly reducing their consumption of electricity.

A lot of berries rot before we can eat them. An anti-ripening agent complexed with cyclodextrins during storage can prevent fruit from ripening too early. The technology also saves energy, as it eliminates the need for additional cooling.

Bioplastics are going to play an increasingly important role going forward. The term bioplastics refers to biopolymers that are either manufactured from renewable raw materials or that are biodegradable.

WACKER silicone- and polymer-based additives not only enhance the options for processing these innovative biopolymers – they also improve the properties of the final product.

Consumers are paying more and more attention to sustainability – and because this trend also encompasses cosmetics, we make silicone components for this sector from 100% biomethanol. That conserves valuable resources.

One of the key starting materials for our silicone sealants is methanol. Because sustainability is becoming an ever more important factor in construction materials, we make sealants from plant-based biomethanol based exclusively on certified biomass rather than on fossil raw materials.

Our polymer binders enhance the performance of tile adhesives, making it possible to lay tiles using the thin-bed technique, which can reduce the cement and sand used by over 60%.

That means that our solutions not only greatly reduce the use of cement, which has a positive impact on our CO2 footprint – they also save significant amounts of sand, one of the world’s most frequently consumed natural resources.

Moisture in masonry increases the risk of mold formation, especially in wet locations and in rooms with showers.

Our polymeric binders allow builders to formulate cementitious sealing slurries for application underneath tiles, where they prevent moisture penetration and ensure the building fabric will last a long time.