Press Photos

Please note our terms of use governing the use of press images. By downloading images from our media database, you agree to these terms of use:

Press images may only be used for press purposes (print, electronic media, online) and may not be edited. Indicating the picture credits (source: Wacker Chemie AG) is obligatory. Images deleted from the media database may no longer be used in future. If a press image is used, please provide us with a copy or link. In other respects, the following copyright information shall apply: www.wacker.com/disclaimer

Category

Reset perimeterVINNAPAS® LL 3112 - Lab Test

Lab test of a dispersion: Depending on the formulation, VINNAPAS® LL 3112 allows highly fire-resistant coatings with fire resistance class F120 to be achieved, which means heat protection for up to two hours.

Order photoVINNAPAS® LL 3112 - Foam Development

In case of a fire, intumescent coatings foam to tens to hundreds of times its original thickness and act as a heat barrier. The new VINNAPAS® LL 3112 binder ensures significant foam development in these coatings, coupled with improved adhesion and strength (photo: Clariant Produkte Deutschland GmbH - 2013).

Order photoFire test: Intumescent Coatings

Fire test: Intumescent coatings encase steel girders and, in case of a fire, form an insulating foam barrier, thus protecting the steel structure from the heat – and dispersions from WACKER play a key role here as a binder (photo: Clariant Produkte Deutschland GmbH - 2013)

Order photoVINNAPAS® EZ 3112

Modern buildings often feature steel skeletons – but when the temperature reaches 500°C, steel frames soften rapidly. To prevent them from buckling within minutes during a fire (left), they are provided with special fire protection coatings, allowing them to resist a fire for much longer (right). The polymer binders VINNAPAS® EZ 3112 and VINNAPAS® EZ 3066 ensure significant foam development in these coatings, coupled with improved adhesion and strength.

Order photoETONIS® 260

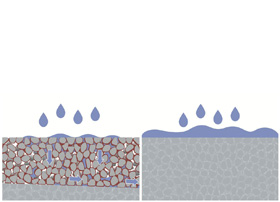

Water-permeability test: Open-pored concrete modified with ETONIS® 260 facilitates the transport of moisture (left), while on conventional solid concrete, water builds up and runs off slowly (right). This results in far fewer cracks forming in the new concrete and augments its resistance to frost and road salts.

Order photo