Press Photos

Please note our terms of use governing the use of press images. By downloading images from our media database, you agree to these terms of use:

Press images may only be used for press purposes (print, electronic media, online) and may not be edited. Indicating the picture credits (source: Wacker Chemie AG) is obligatory. Images deleted from the media database may no longer be used in future. If a press image is used, please provide us with a copy or link. In other respects, the following copyright information shall apply: www.wacker.com/disclaimer

Category

Reset perimeterSILRES® BS resin silicone emulsion paint

For effective facade protection: Silicone resin emulsion paints based on SILRES® BS feature very high water-vapor permeability, extremely low water absorption and extreme durability.

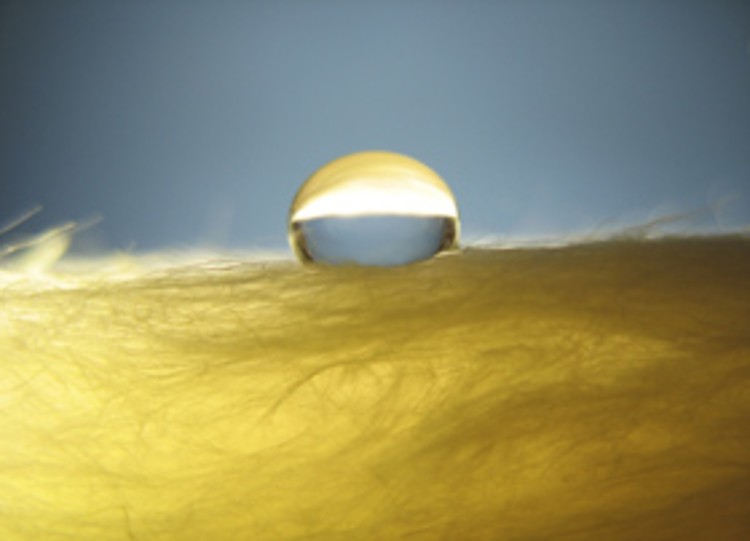

Download picture (280x202px) (JPG, 13 KB)llustration Drop Test

This droplet penetration test shows that water-repellent silicone fluid emulsions from WACKER reliably protect mineral wool from moisture. Thanks to its low viscosity, the new SILRES® BS 5137 can be processed very efficiently.

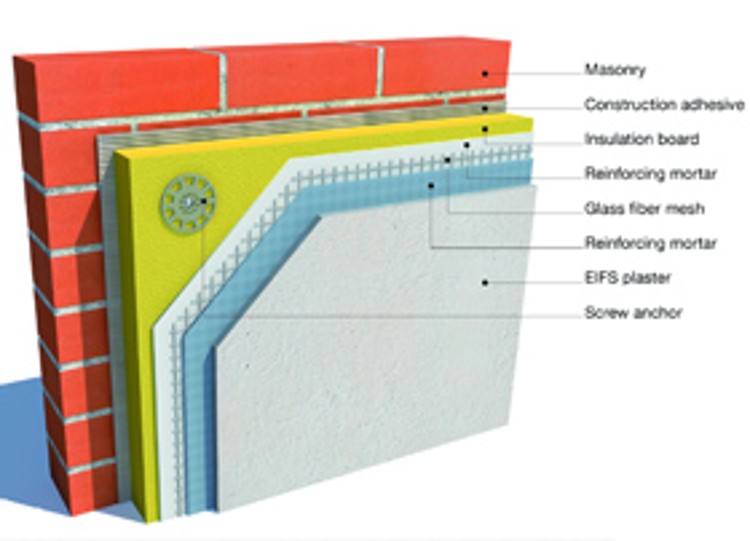

Download picture (280x202px) (JPG, 24 KB)llustration EIFS

Modern EIFS for building insulation consist of a multi-layered material composite. But only the addition of a dispersible polymer powder creates a firm bond to the insulating material and thus a permanently stable insulation system.

Download picture (280x202px) (JPG, 34 KB)Gotthard Tunnel - Renovating

Renovating the Gotthard tunnel: specialists used compressed air to apply the silane impregnating agent.

Download picture (280x202px) (JPG, 32 KB)Gotthard Tunnel - Completely closed

Completely closed to traffic: to provide protection against moisture and salt ingress, the ceiling of the Gotthard tunnel was impregnated in late September with a specialty silane cream made by WACKER, the Munich-based chemical group.

Download picture (280x202px) (JPG, 28 KB)