Press Photos

Please note our terms of use governing the use of press images. By downloading images from our media database, you agree to these terms of use:

Press images may only be used for press purposes (print, electronic media, online) and may not be edited. Indicating the picture credits (source: Wacker Chemie AG) is obligatory. Images deleted from the media database may no longer be used in future. If a press image is used, please provide us with a copy or link. In other respects, the following copyright information shall apply: www.wacker.com/disclaimer

Category

Reset perimeterCOEE in Pangyo, South Korea

The Center of Electronics Excellence (COEE) in Pangyo, South Korea, where WACKER develops specialty silicones for the automotive, lighting and electronics industries. Production of these silicones will be transferred to the new site in Jincheon.

Download picture (230x153px) (JPG, 41 KB)WETSOFT® NE 750 - Drop Test

The drop test proves that textiles that have been treated with WETSOFT® NE 750 are extremely absorbent. The emulsion penetrates to the base of the fabric, even with a long pile, which facilitates water uptake. Re-dying of the material is not a problem.

Download picture (230x153px) (JPG, 32 KB)WETSOFT® NE 750

The new softener WETSOFT® NE 750 is ideal for primary finishing of towels and high-quality materials. The treatment yields textiles that are full and soft yet absorbent. The hydrophilic fabric softener is available as a water-free concentrate with a high solids content.

Download picture (230x153px) (JPG, 41 KB)“Young Scientists” competition - Prinz-Carl-Palais

Highly motivated for the German finals: the winners of Bavaria’s “Young Scientists” competition were honored by State Chancellery Minister Dr. Marcel Huber (far right) and WACKER Executive Board member Auguste Willems (second from left) at Munich’s Prinz-Carl-Palais.

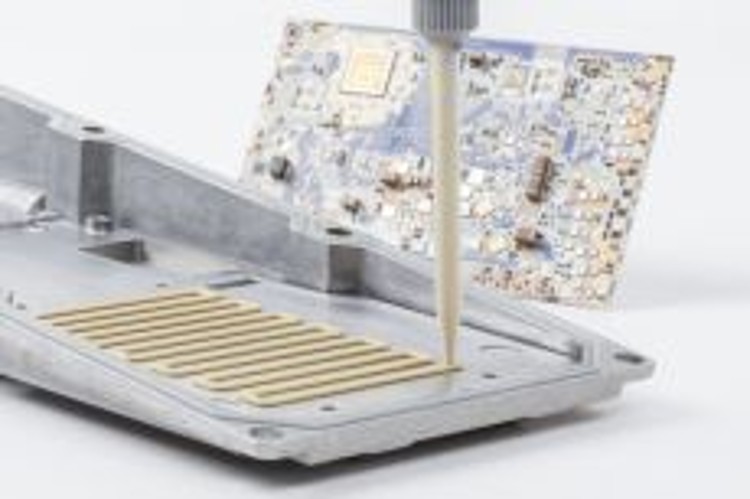

Download picture (230x153px) (JPG, 44 KB)SEMICOSIL® 961 TC

The heat-conducting SEMICOSIL® 961 TC silicone filler from WACKER is applied directly to the heat sink. Once the electrical circuit is pressed on, the gap filler cures to form a soft, cushioning silicone layer that optimally transfers heat to the heat sink.

Download picture (230x153px) (JPG, 51 KB)