Our system has noticed that you are based in , but the current country setting is . Do you still want to change your country?

- Home

- Products & Services

- Applications

- Energy

- Cables & Wires

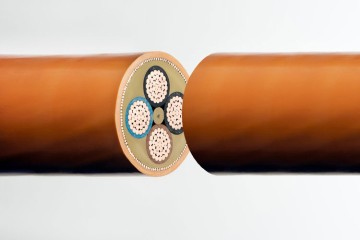

Cables & Wires

WACKER offers a comprehensive portfolio of peroxide- and platinum-cure HTV silicone rubber as well as addition-cure silicone gels for use as insulating material in various cables and wires.

Benefits

- High heat resistance to 300 °C (far in excess of 1,000 °C is possible for one-time measurements)

- Very good dielectric strength

- Excellent mechanical strength

- High tear strength

Benefits

- Very good heat resistance over very long periods

- High tear strength

- Excellent UV resistance

- High color and design flexibility

- Excellent mechanical strength

- No toxic products released in the event of fire (flame resistant)

- Peroxide-cure, electrically conducting ELASTOSIL® HTV silicone rubber with high tensile strength for applications requiring special abrasion or notch resistance

- Peroxide-cure, oil- and heat-resistant HTV silicone rubber for cables offering superior media resistance

- Addition-cure silicone gels

Benefits

- Excellent heat resistance to 300 °C (far in excess of 1,000 °C is possible for one-time measurements)

- High dielectric strength

- Excellent mechanical strength

- High tensile strength and tear strength

Benefits

- High heat resistance to 300 °C

- Very good resistance to temperatures of 180 °C over very long periods

- High tear strength

- Excellent UV resistance

- High color and design flexibility

- Excellent mechanical strength

- No toxic products released in the event of fire (flame resistant)

Benefits

- High heat resistance to 250 °C over long periods and briefly to 300 °C

- High tear strength prevents damage to ignition cables during repair or due to sharp edges in the engine compartment.

- Extremely high resistance to cyclic, thermal stress

- Excellent mechanical and chemical resistance

- Highly insulating

Applications

- Ignition cables

- Battery cables

- Power lines

Find out more about our battery and hybrid cables under “E-Mobility”.

Battery and hybrid cables in E-mobility