Press Photos

Please note our terms of use governing the use of press images. By downloading images from our media database, you agree to these terms of use:

Press images may only be used for press purposes (print, electronic media, online) and may not be edited. Indicating the picture credits (source: Wacker Chemie AG) is obligatory. Images deleted from the media database may no longer be used in future. If a press image is used, please provide us with a copy or link. In other respects, the following copyright information shall apply: www.wacker.com/disclaimer

Category

Reset perimeterAlz canal

The 16-km long Alz canal in Burghausen (Germany) was renovated and sealed using polymer-modified sealing slurries to prevent water leakage.

Download picture (280x202px) (JPG, 59 KB)Tile adhesive - thin-bed technique

Today’s routine thin-bed technique was enabled by tile adhesives containing VINNAPAS®. The benefits include far less needed material and significantly lower costs, as well as time savings and simpler handling thanks to enhanced flexibility and a longer open time.

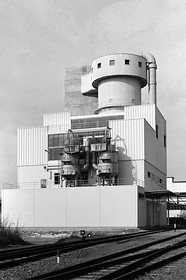

Download picture (2303x1535px) (JPG, 949 KB)Burghausen - Historic Spraydryer

The first spray dryer for VINNAPAS® polymer powders went on stream at WACKER’s parent plant in Burghausen in 1957. The facility produced 1,200 metric tons per year. To date, over 1 million metric tons of powder have been sold, and in summer 2007, WACKER Burghausen will commission the world’s largest plant with an annual capacity of 30,000 tons.

Download picture (186x280px) (JPG, 19 KB)Burghausen - Spray-drying towers

Spray-drying towers for dispersible polymer powders at WACKER’s parent plant in Burghausen, Germany. With the construction of a new 50,000-metric-ton spray dryer, WACKER is strengthening its position as a market and technology leader in this field.

Download picture (280x187px) (JPG, 25 KB)VINNAPAS® Surface

Self-leveling flooring and troweling compounds modified with VINNAPAS® produce an extraordinarily smooth, even and fine pored surface (left), as opposed to formulations without or with conventional binders (right). Even a small amount of VINNAPAS® significantly enhances abrasion resistance, tensile strength in bending as well as compressive strength and provides crack-free setting

Download picture (2138x1535px) (JPG, 723 KB)