WACKER Plans New Production Site for Silicone Specialties in the Czech Republic

Munich, Jan 11, 2024

Wacker Chemie AG plans to further expand its silicone specialties business and is reorganizing its production operations in Europe. A new production site for silicones is to be built in Karlovy Vary in the Czech Republic. The main drivers of this expansion measure are megatrends such as electromobility and renewable energies which require silicones from WACKER. Production is expected to start at the end of 2025. In the first step of the project, the Group would create up to 200 jobs. The investment volume is in the low triple-digit million euro range.

The new production site in Karlovy Vary is intended to complement WACKER’s existing integrated production sites in Germany – namely Burghausen and Nünchritz –, as well as the site in Pilsen, which is specialized in the area of electromobility. “Karlovy Vary will be an important pillar for our silicone activities in Europe, especially when it comes to the production of customized silicone compounds. With this project, we will be creating important conditions for further optimizing our production processes and making us even more flexible within our integrated production system comprising four locations. Our customers stand to benefit from specific product solutions – reliable, highly efficient and top quality”, says WACKER Executive Board member Christian Kirsten.

The main drivers for the silicone business are megatrends such as electromobility, renewable energies and the expansion of electricity grids. “Our grades of silicone rubber are in demand in all key growth markets”, states Kirsten. “Customized silicone elastomers are especially needed where conventional materials cannot or can no longer meet the high and ever-increasing requirements. In order to be able to meet the growing demand for such solutions in the long term, we need to lay the groundwork for it now.”

The new site in Karlovy Vary will focus on the production of room-temperature-vulcanizing specialty silicones. Production is scheduled to start at the end of 2025. Later, high-temperature-vulcanizing silicone compounds will also be produced there. In total, WACKER plans to invest a sum in the low triple-digit million euro range and to create around 200 jobs by 2028. Further personnel requirements in following years are also on the cards. When fully operational, Karlovy Vary will be able to supply over 20,000 metric tons of custom-made silicones per year.

The raw materials required for production - polymers, fillers and additives - are to be delivered from Burghausen and mixed in Karlovy Vary to manufacture ready-to-use silicones, also referred to as compounds. “By bundling our production capacities for compounds in Karlovy Vary, we can utilize our fully continuous plants in Burghausen even better, further increase our efficiency and accelerate the planned automation of our processes”, emphasizes Thomas Koini, president of the WACKER SILICONES business division. “In future, our site in Pilsen will focus on the growing market for silicone gels and thermally conductive silicones. Such products are in high demand in the electromobility sector in particular. This means that our existing plants will also benefit from the new production concept.”

WACKER is cooperating with the US real estate developer Panattoni on the construction of the new site in Karlovy Vary. Development work on the site is set to begin shortly, and construction work on the building is scheduled to start in the second quarter of 2024, subject to approval by the authorities. The Czech real estate group Accolade is the owner of the 23,000-square-meter site and the eventual production building on the outskirts of Karlovy Vary.

About WACKER SILICONES

WACKER SILICONES is one of the largest silicone manufacturers worldwide with over 2,800 highly specialized and innovative products. The division’s portfolio ranges from silicone fluids, emulsions, resins, elastomers and sealants to silanes, silane-terminated polymers and pyrogenic silica. These stand out due to their significant value-adding potential – enhancing both the benefits and performance of customers’ end products. WACKER SILICONES’ products find application in such sectors as automotive engineering, construction, chemicals, cosmetics, medical technology, energy and electronics, and paper and textiles.

Presspicture

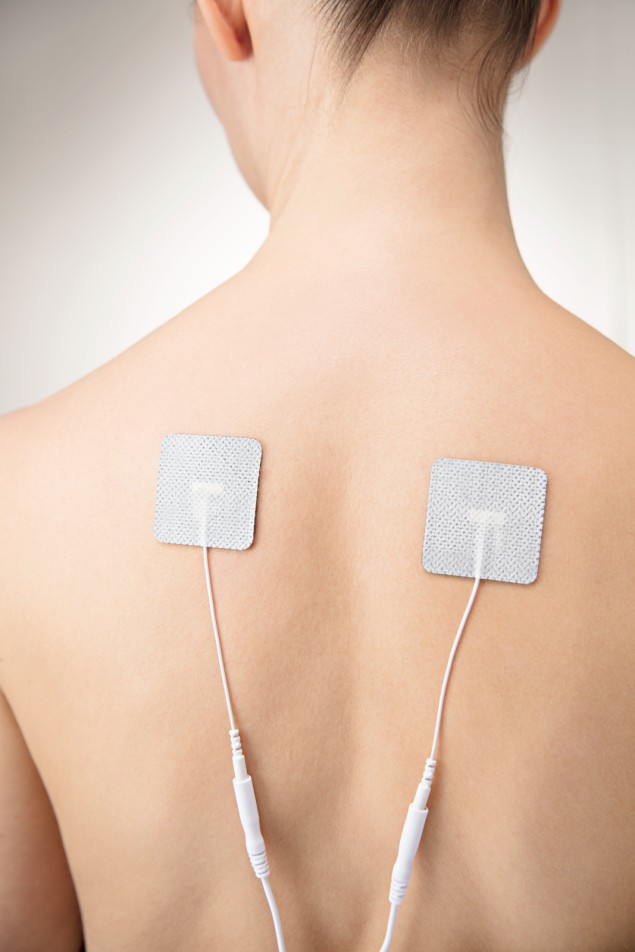

Silicone Rubber Medical

Silicone Rubber Medical

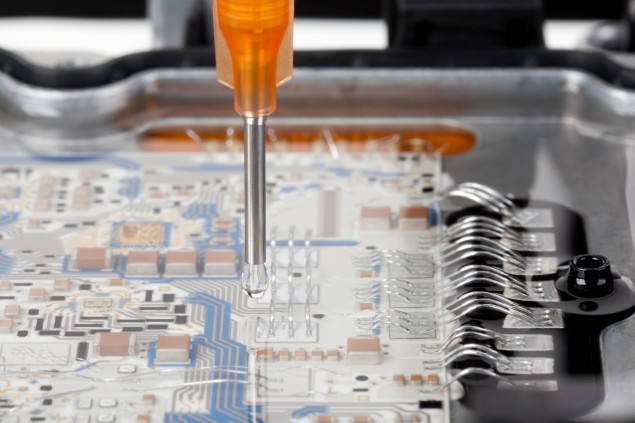

Download picture (JPG, 476 KB)Silicone Encapsulant

Silicone Encapsulant

Download picture (JPG, 462 KB)Emobility Battery

Emobility Battery

Download picture (JPG, 313 KB)Contact

Wacker Chemie AG

Media Relations

Florian Degenhart

Tel. +49 89 6279-1601

Email florian.degenhart@wacker.com

Send Message

Download

Press Information

(PDF | 253 KB)