Our system has noticed that you are based in United States, but the current country setting is Ireland. Do you still want to change your country?

- Home

- Products & Services

- Applications

- Energy

- Cables & Wires

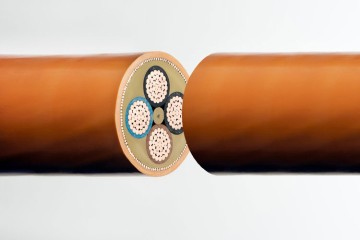

Cables & Wires

WACKER offers a comprehensive portfolio of peroxide- and platinum-cure HTV silicone rubber as well as addition-cure silicone gels for use as insulating material in various cables and wires.

Benefits

- High heat resistance to 300 °C (far in excess of 1,000 °C is possible for one-time measurements)

- Very good dielectric strength

- Excellent mechanical strength

- High tear strength

Product Recommendations

Sorry, no results are available for your filter criteria and selected country. Please contact one of our sales offices.

|

Products

|

Technical data

|

Product properties

|

||||||

|---|---|---|---|---|---|---|---|---|

| Appearance | Hardness Shore A | Tensile strength | Elongation at break | Tear strength | Compression Set | Specific Features | ||

| ELASTOSIL® R 502/75 MH E | white white | 71[1] 71[1] | 8.7 N/mm²[2] 8.7 N/mm²[2] | 262 %[3] 262 %[3] | 17.7 N/mm[4] 17.7 N/mm[4] | - - | Flame retardant, High LOI, Ceramifying | |

| ELASTOSIL® R 502/75 OH | white white | 73[1] 73[1] | 8.7 N/mm²[2] 8.7 N/mm²[2] | 400 %[3] 400 %[3] | 24 N/mm[4] 24 N/mm[4] | 56 %[5] 56 %[5] | Ceramifying | |

| ELASTOSIL® R 512/70 OH | opaque opaque | 70[1] 70[1] | 6.5 N/mm²[2] 6.5 N/mm²[2] | 300 %[3] 300 %[3] | 18 N/mm[4] 18 N/mm[4] | 41 %[5] 41 %[5] | Ceramifying | |

[1] Hardness Shore A | DIN ISO 48-4, [2] Tensile strength | ISO 37 type 1, [3] Elongation at break | ISO 37 type 1, [4] Tear strength | ASTM D 624 B, [5] Compression Set | 22 h | 175 °C | DIN ISO 815-1 type B method A, [] Suited, [] Well suited, [] Ideally suited

Benefits

- Very good heat resistance over very long periods

- High tear strength

- Excellent UV resistance

- High color and design flexibility

- Excellent mechanical strength

- No toxic products released in the event of fire (flame resistant)

Product Recommendations

Sorry, no results are available for your filter criteria and selected country. Please contact one of our sales offices.

|

Products

|

Technical data

|

Product properties

|

||||||

|---|---|---|---|---|---|---|---|---|

| Appearance | Hardness Shore A | Tensile strength | Elongation at break | Tear strength | Compression Set | Specific Features | ||

| ELASTOSIL® R 501/75 OH | white white | 68[1] 68[1] | 7.3 N/mm²[2] 7.3 N/mm²[2] | 500 %[3] 500 %[3] | 34 N/mm[4] 34 N/mm[4] | 89 %[5] 89 %[5] | Flame retardant, Heat resistant, High LOI, High tear-resistant | |

| ELASTOSIL® R 770/50 OH | white white | 45[1] 45[1] | 9.0 N/mm²[2] 9.0 N/mm²[2] | 670 %[3] 670 %[3] | 40 N/mm[4] 40 N/mm[4] | 15 %[5] 15 %[5] | Flame retardant, High LOI | |

| ELASTOSIL® R 770/60 OH | white white | 63[1] 63[1] | 4.0 N/mm²[2] 4.0 N/mm²[2] | 420 %[3] 420 %[3] | 14 N/mm[4] 14 N/mm[4] | 56 %[6] 56 %[6] | Flame retardant, High LOI | |

| ELASTOSIL® R 770/75 OH | white white | 72[1] 72[1] | 3.8 N/mm²[2] 3.8 N/mm²[2] | 350 %[3] 350 %[3] | 15 N/mm[4] 15 N/mm[4] | 59 %[6] 59 %[6] | Flame retardant, High LOI | |

[1] Hardness Shore A | DIN ISO 48-4, [2] Tensile strength | ISO 37 type 1, [3] Elongation at break | ISO 37 type 1, [4] Tear strength | ASTM D 624 B, [5] Compression Set | 22 h | 175 °C | DIN ISO 815-1 type B method A, [6] Compression Set | 22 h | 175 °C | DIN ISO 815-1 type B method A | post-cured 4 h / 150 °C, [] Suited, [] Well suited, [] Ideally suited

- Peroxide-cure, electrically conducting ELASTOSIL® HTV silicone rubber with high tensile strength for applications requiring special abrasion or notch resistance

- Peroxide-cure, oil- and heat-resistant HTV silicone rubber for cables offering superior media resistance

- Addition-cure silicone gels

Benefits

- Excellent heat resistance to 300 °C (far in excess of 1,000 °C is possible for one-time measurements)

- High dielectric strength

- Excellent mechanical strength

- High tensile strength and tear strength

产品推荐

抱歉,没有找到符合您的筛选条件的结果

|

个产品

|

技术数据

|

Product properties

|

||||||

|---|---|---|---|---|---|---|---|---|

| Appearance | Hardness Shore A | Tensile strength | Elongation at break | Tear strength | Compression Set | Specific Features | ||

| ELASTOSIL® R 401/60 KX | transparent transparent | 59[1] 59[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 460 %[3] 460 %[3] | 25 N/mm[4] 25 N/mm[4] | 25 %[5] 25 %[5] | Food-contact, High green strength | |

| ELASTOSIL® R 401/60 S | transparent transparent | 60[1] 60[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 550 %[3] 550 %[3] | 26 N/mm[4] 26 N/mm[4] | 16 %[5] 16 %[5] | Food-contact, General purpose | |

| ELASTOSIL® R 401/70 S | transparent transparent | 70[1] 70[1] | 11.3 N/mm²[2] 11.3 N/mm²[2] | 530 %[3] 530 %[3] | 31 N/mm[4] 31 N/mm[4] | 22 %[5] 22 %[5] | Food-contact, General purpose | |

| ELASTOSIL® R 510/60 S | translucent translucent | 60[1] 60[1] | 10.2 N/mm²[2] 10.2 N/mm²[2] | 400 %[3] 400 %[3] | 22 N/mm[4] 22 N/mm[4] | 31 %[6] 31 %[6] | Heat resistant, General purpose | |

| ELASTOSIL® R 510/70 S | translucent translucent | 70[1] 70[1] | 9.4 N/mm²[2] 9.4 N/mm²[2] | 340 %[3] 340 %[3] | 21 N/mm[4] 21 N/mm[4] | 48 %[6] 48 %[6] | Heat resistant, General purpose | |

[1] Hardness Shore A | DIN ISO 48-4, [2] Tensile strength | ISO 37 type 1, [3] Elongation at break | ISO 37 type 1, [4] Tear strength | ASTM D 624 B, [5] Compression Set | 22 h | 175 °C | DIN ISO 815-1 type B method A | post-cured 4 h / 200 °C, [6] Compression Set | 22 h | 175 °C | DIN ISO 815-1 type B method A, [] 适合, [] 非常适合, [] 极其适合

Benefits

- High heat resistance to 300 °C

- Very good resistance to temperatures of 180 °C over very long periods

- High tear strength

- Excellent UV resistance

- High color and design flexibility

- Excellent mechanical strength

- No toxic products released in the event of fire (flame resistant)

产品推荐

抱歉,没有找到符合您的筛选条件的结果

|

个产品

|

技术数据

|

Product properties

|

|||||||

|---|---|---|---|---|---|---|---|---|---|

| Appearance | 外观 | Shore density A | Breaking strength | 断裂伸长率 | Tear-growth resistance | 压缩变形 | 具体特征 | ||

| ELASTOSIL® R 401/60 KX | transparent transparent | - - | 59[1] 59[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 460 %[3] 460 %[3] | 25 N/mm[4] 25 N/mm[4] | 25 %[5] 25 %[5] | 食品接触, 高生坯强度 | |

| ELASTOSIL® R 401/60 S | - - | transparent transparent | 60[1] 60[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 550 %[3] 550 %[3] | 26 N/mm[4] 26 N/mm[4] | 16 %[5] 16 %[5] | 食品接触, 通用型 | |

| ELASTOSIL® R 401/70 S | - - | transparent transparent | 70[1] 70[1] | 11.3 N/mm²[2] 11.3 N/mm²[2] | 530 %[3] 530 %[3] | 31 N/mm[4] 31 N/mm[4] | 22 %[5] 22 %[5] | 食品接触, 通用型 | |

| ELASTOSIL® R 510/60 S | - - | translucent translucent | 60[1] 60[1] | 10.2 N/mm²[2] 10.2 N/mm²[2] | 400 %[3] 400 %[3] | 22 N/mm[4] 22 N/mm[4] | 31 %[6] 31 %[6] | 耐热性, 通用型 | |

| ELASTOSIL® R 510/70 S | - - | translucent translucent | 70[1] 70[1] | 9.4 N/mm²[2] 9.4 N/mm²[2] | 340 %[3] 340 %[3] | 21 N/mm[4] 21 N/mm[4] | 48 %[6] 48 %[6] | 耐热性, 通用型 | |

[1] Shore density A | DIN ISO 48-4, [2] Breaking strength | ISO 37 type 1, [3] 断裂伸长率 | ISO 37 type 1, [4] Tear-growth resistance | ASTM D 624 B, [5] 压缩变形 | 22 h | 175 °C | DIN ISO 815-1 type B method A | post-cured 4 h / 200 °C, [6] 压缩变形 | 22 h | 175 °C | DIN ISO 815-1 type B method A, [] 适合, [] 非常适合, [] 极其适合

Benefits

- High heat resistance to 250 °C over long periods and briefly to 300 °C

- High tear strength prevents damage to ignition cables during repair or due to sharp edges in the engine compartment.

- Extremely high resistance to cyclic, thermal stress

- Excellent mechanical and chemical resistance

- Highly insulating

Applications

- Ignition cables

- Battery cables

- Power lines

Produktempfehlungen

Für Ihre Filterkriterien und das gewählte Land sind leider keine Ergebnisse verfügbar. Bitte kontaktieren Sie unseren Vertrieb.

|

Produkte

|

Technische Daten

|

Produktmerkmale

|

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Appearance | 外观 | Shore density A | Breaking strength | Reißfestigkeit | Reißdehnung | Weiterreißwiderstand | Druckverformungsrest | Spezifische Merkmale | ||

| ELASTOSIL® R 401/60 KX | transparent transparent | - - | 59[1] 59[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | - - | 460 %[4] 460 %[4] | 25 N/mm[5] 25 N/mm[5] | 25 %[6] 25 %[6] | Lebensmittelkontakt, hohe Fellfestigkeit | |

| ELASTOSIL® R 401/60 S | transparent transparent | - - | 60[1] 60[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | - - | 550 %[4] 550 %[4] | 26 N/mm[5] 26 N/mm[5] | 16 %[6] 16 %[6] | Lebensmittelkontakt, Standard | |

| ELASTOSIL® R 401/70 S | transparent transparent | - - | 70[1] 70[1] | 11.3 N/mm²[2] 11.3 N/mm²[2] | - - | 530 %[4] 530 %[4] | 31 N/mm[5] 31 N/mm[5] | 22 %[6] 22 %[6] | Lebensmittelkontakt, Standard | |

| ELASTOSIL® R 420/60 S | transparent transparent | - - | 62[1] 62[1] | - - | 11.0 N/mm²[3] 11.0 N/mm²[3] | 660 %[4] 660 %[4] | 43 N/mm[5] 43 N/mm[5] | 25 %[6] 25 %[6] | Lebensmittelkontakt, hoch weiterreissfest | |

| ELASTOSIL® R 420/70 S | transparent transparent | - - | 72[1] 72[1] | - - | 10.0 N/mm²[3] 10.0 N/mm²[3] | 570 %[4] 570 %[4] | 45 N/mm[5] 45 N/mm[5] | 38 %[6] 38 %[6] | Lebensmittelkontakt, hoch weiterreissfest | |

| ELASTOSIL® R 510/60 S | translucent translucent | - - | 60[1] 60[1] | - - | 10.2 N/mm²[3] 10.2 N/mm²[3] | 400 %[4] 400 %[4] | 22 N/mm[5] 22 N/mm[5] | 31 %[7] 31 %[7] | hitzebeständig, Standard | |

| ELASTOSIL® R 510/70 S | translucent translucent | - - | 70[1] 70[1] | - - | 9.4 N/mm²[3] 9.4 N/mm²[3] | 340 %[4] 340 %[4] | 21 N/mm[5] 21 N/mm[5] | 48 %[7] 48 %[7] | hitzebeständig, Standard | |

| ELASTOSIL® R 570/70 OH | - - | black black | 71[1] 71[1] | - - | 7.4 N/mm²[3] 7.4 N/mm²[3] | 180 %[4] 180 %[4] | 13 N/mm[5] 13 N/mm[5] | 29 %[6] 29 %[6] | elektrisch leitfähig | |

| ELASTOSIL® R 573/50 A/B | - - | black black | 50[1] 50[1] | - - | 5.5 N/mm²[3] 5.5 N/mm²[3] | 340 %[4] 340 %[4] | 13 N/mm[5] 13 N/mm[5] | 30 %[8] 30 %[8] | elektrisch leitfähig, zweikomponentig, Additionsvernetzend | |

| ELASTOSIL® R 573/70 A/B | - - | black black | 71[1] 71[1] | - - | 6.2 N/mm²[3] 6.2 N/mm²[3] | 246 %[4] 246 %[4] | 14 N/mm[5] 14 N/mm[5] | 29 %[8] 29 %[8] | elektrisch leitfähig, zweikomponentig, Additionsvernetzend | |

| ELASTOSIL® R plus 4305/70 | - - | transparent transparent | 70[1] 70[1] | - - | 9.1 N/mm²[3] 9.1 N/mm²[3] | 600 %[4] 600 %[4] | 39 N/mm[5] 39 N/mm[5] | 14 %[6] 14 %[6] | zweikomponentig, Lebensmittelkontakt, niedriger Druckverformungsrest, Additionsvernetzend | |

| ELASTOSIL® R plus 4305/80 | - - | transparent transparent | 80[1] 80[1] | - - | 7.8 N/mm²[3] 7.8 N/mm²[3] | 310 %[4] 310 %[4] | 21 N/mm[5] 21 N/mm[5] | 17 %[6] 17 %[6] | zweikomponentig, Lebensmittelkontakt, niedriger Druckverformungsrest, Additionsvernetzend | |

| ELASTOSIL® R plus 5305/70 | - - | transparent transparent | 70[1] 70[1] | - - | 9.2 N/mm²[3] 9.2 N/mm²[3] | 590 %[4] 590 %[4] | 42 N/mm[5] 42 N/mm[5] | 10 %[6] 10 %[6] | zweikomponentig, Additionsvernetzend | |

[1] Shore density A | DIN ISO 48-4, [2] Breaking strength | ISO 37 type 1, [3] Reißfestigkeit | ISO 37 Type 1, [4] Reißdehnung | ISO 37 Type 1, [5] Weiterreißwiderstand | ASTM D 624 B, [6] Druckverformungsrest | 22 h | 175 °C | DIN ISO 815-1 Typ B Methode A | post-cured 4 h / 200 °C, [7] Druckverformungsrest | 22 h | 175 °C | DIN ISO 815-1 Typ B Methode A, [8] Druckverformungsrest | 22 h | 175 °C | DIN ISO 815-1 Typ B Methode A | post-cured 0.5 h / 200 °C, [] Geeignet, [] Gut geeignet, [] Ideal geeignet

Find out more about our battery and hybrid cables under “E-Mobility”.

Battery and hybrid cables in E-mobility产品推荐

抱歉,没有找到符合您的筛选条件的结果

|

个产品

|

技术数据

|

Product properties

|

|||||||

|---|---|---|---|---|---|---|---|---|---|

| Appearance | 外观 | Shore density A | Breaking strength | 断裂伸长率 | Tear-growth resistance | 压缩变形 | 具体特征 | ||

| ELASTOSIL® R 401/60 KX | transparent transparent | - - | 59[1] 59[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 460 %[3] 460 %[3] | 25 N/mm[4] 25 N/mm[4] | 25 %[5] 25 %[5] | 食品接触, 高生坯强度 | |

| ELASTOSIL® R 401/60 S | transparent transparent | - - | 60[1] 60[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 550 %[3] 550 %[3] | 26 N/mm[4] 26 N/mm[4] | 16 %[5] 16 %[5] | 食品接触, 通用型 | |

| ELASTOSIL® R 401/70 S | transparent transparent | - - | 70[1] 70[1] | 11.3 N/mm²[2] 11.3 N/mm²[2] | 530 %[3] 530 %[3] | 31 N/mm[4] 31 N/mm[4] | 22 %[5] 22 %[5] | 食品接触, 通用型 | |

| ELASTOSIL® R 420/60 S | transparent transparent | - - | 62[1] 62[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 660 %[3] 660 %[3] | 43 N/mm[4] 43 N/mm[4] | 25 %[5] 25 %[5] | 食品接触, 高抗撕裂性能 | |

| ELASTOSIL® R 420/70 S | transparent transparent | - - | 72[1] 72[1] | 10.0 N/mm²[2] 10.0 N/mm²[2] | 570 %[3] 570 %[3] | 45 N/mm[4] 45 N/mm[4] | 38 %[5] 38 %[5] | 食品接触, 高抗撕裂性能 | |

| ELASTOSIL® R plus 4305/70 | transparent transparent | - - | 70[1] 70[1] | 9.1 N/mm²[2] 9.1 N/mm²[2] | 600 %[3] 600 %[3] | 39 N/mm[4] 39 N/mm[4] | 14 %[5] 14 %[5] | 双组分, 食品接触, 低压缩形变率, 加成固化 | |

| ELASTOSIL® R plus 4305/80 | transparent transparent | - - | 80[1] 80[1] | 7.8 N/mm²[2] 7.8 N/mm²[2] | 310 %[3] 310 %[3] | 21 N/mm[4] 21 N/mm[4] | 17 %[5] 17 %[5] | 双组分, 食品接触, 低压缩形变率, 加成固化 | |

| ELASTOSIL® R plus 5305/70 | - - | transparent transparent | 70[1] 70[1] | 9.2 N/mm²[2] 9.2 N/mm²[2] | 590 %[3] 590 %[3] | 42 N/mm[4] 42 N/mm[4] | 10 %[5] 10 %[5] | 双组分, 加成固化 | |

[1] Shore density A | DIN ISO 48-4, [2] Breaking strength | ISO 37 type 1, [3] 断裂伸长率 | ISO 37 type 1, [4] Tear-growth resistance | ASTM D 624 B, [5] 压缩变形 | 22 h | 175 °C | DIN ISO 815-1 type B method A | post-cured 4 h / 200 °C, [] 适合, [] 非常适合, [] 极其适合