Our system has noticed that you are based in United States, but the current country setting is Saudi Arabia. Do you still want to change your country?

- Home

- Products & Services

- Applications

- Energy

- Cables & Wires

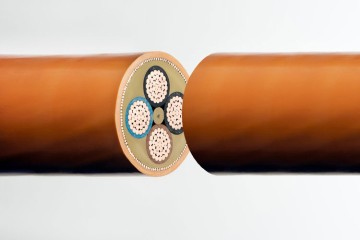

Cables & Wires

WACKER offers a comprehensive portfolio of peroxide- and platinum-cure HTV silicone rubber as well as addition-cure silicone gels for use as insulating material in various cables and wires.

Benefits

- High heat resistance to 300 °C (far in excess of 1,000 °C is possible for one-time measurements)

- Very good dielectric strength

- Excellent mechanical strength

- High tear strength

Product Recommendations

Sorry, no results are available for your filter criteria and selected country. Please contact one of our sales offices.

|

Products

|

Technical data

|

Product properties

|

||||||

|---|---|---|---|---|---|---|---|---|

| Appearance | Hardness Shore A | Tensile strength | Elongation at break | Tear strength | Compression Set | Specific Features | ||

| ELASTOSIL® R 502/75 MH E | white white | 71[1] 71[1] | 8.7 N/mm²[2] 8.7 N/mm²[2] | 262 %[3] 262 %[3] | 17.7 N/mm[4] 17.7 N/mm[4] | - - | Flame retardant, High LOI, Ceramifying | |

| ELASTOSIL® R 502/75 OH | white white | 73[1] 73[1] | 8.7 N/mm²[2] 8.7 N/mm²[2] | 400 %[3] 400 %[3] | 24 N/mm[4] 24 N/mm[4] | 56 %[5] 56 %[5] | Ceramifying | |

| ELASTOSIL® R 512/70 OH | opaque opaque | 70[1] 70[1] | 6.5 N/mm²[2] 6.5 N/mm²[2] | 300 %[3] 300 %[3] | 18 N/mm[4] 18 N/mm[4] | 41 %[5] 41 %[5] | Ceramifying | |

[1] Hardness Shore A | DIN ISO 48-4, [2] Tensile strength | ISO 37 type 1, [3] Elongation at break | ISO 37 type 1, [4] Tear strength | ASTM D 624 B, [5] Compression Set | 22 h | 175 °C | DIN ISO 815-1 type B method A, [] Suited, [] Well suited, [] Ideally suited

Benefits

- Very good heat resistance over very long periods

- High tear strength

- Excellent UV resistance

- High color and design flexibility

- Excellent mechanical strength

- No toxic products released in the event of fire (flame resistant)

Produktempfehlungen

Für Ihre Filterkriterien und das gewählte Land sind leider keine Ergebnisse verfügbar. Bitte kontaktieren Sie unseren Vertrieb.

|

Produkte

|

Technische Daten

|

Produktmerkmale

|

|||||||

|---|---|---|---|---|---|---|---|---|---|

| Appearance | Hardness Shore A | Reißfestigkeit | Tensile strength | Reißdehnung | Weiterreißwiderstand | Druckverformungsrest | Spezifische Merkmale | ||

| ELASTOSIL® R 501/75 OH | white white | 68[1] 68[1] | - - | 7.3 N/mm²[2] 7.3 N/mm²[2] | 500 %[4] 500 %[4] | 34 N/mm[5] 34 N/mm[5] | 89 %[6] 89 %[6] | schwer entflammbar, hitzebeständig, hoher LOI, hoch weiterreissfest | |

| ELASTOSIL® R 770/50 OH | white white | 45[1] 45[1] | 9.0 N/mm²[3] 9.0 N/mm²[3] | - - | 670 %[4] 670 %[4] | 40 N/mm[5] 40 N/mm[5] | 15 %[6] 15 %[6] | schwer entflammbar, hoher LOI | |

| ELASTOSIL® R 770/60 OH | white white | 63[1] 63[1] | 4.0 N/mm²[3] 4.0 N/mm²[3] | - - | 420 %[4] 420 %[4] | 14 N/mm[5] 14 N/mm[5] | 56 %[7] 56 %[7] | schwer entflammbar, hoher LOI | |

| ELASTOSIL® R 770/75 OH | white white | 72[1] 72[1] | 3.8 N/mm²[3] 3.8 N/mm²[3] | - - | 350 %[4] 350 %[4] | 15 N/mm[5] 15 N/mm[5] | 59 %[7] 59 %[7] | schwer entflammbar, hoher LOI | |

[1] Hardness Shore A | DIN ISO 48-4, [2] Tensile strength | ISO 37 type 1, [3] Reißfestigkeit | ISO 37 Type 1, [4] Reißdehnung | ISO 37 Type 1, [5] Weiterreißwiderstand | ASTM D 624 B, [6] Druckverformungsrest | 22 h | 175 °C | DIN ISO 815-1 Typ B Methode A, [7] Druckverformungsrest | 22 h | 175 °C | DIN ISO 815-1 Typ B Methode A | post-cured 4 h / 150 °C, [] Geeignet, [] Gut geeignet, [] Ideal geeignet

- Peroxide-cure, electrically conducting ELASTOSIL® HTV silicone rubber with high tensile strength for applications requiring special abrasion or notch resistance

- Peroxide-cure, oil- and heat-resistant HTV silicone rubber for cables offering superior media resistance

- Addition-cure silicone gels

Benefits

- Excellent heat resistance to 300 °C (far in excess of 1,000 °C is possible for one-time measurements)

- High dielectric strength

- Excellent mechanical strength

- High tensile strength and tear strength

Produktempfehlungen

Für Ihre Filterkriterien und das gewählte Land sind leider keine Ergebnisse verfügbar. Bitte kontaktieren Sie unseren Vertrieb.

|

Produkte

|

Technische Daten

|

Produktmerkmale

|

||||||

|---|---|---|---|---|---|---|---|---|

| Aussehen | Härte Shore A | Reißfestigkeit | Reißdehnung | Weiterreißwiderstand | Druckverformungsrest | Spezifische Merkmale | ||

| ELASTOSIL® R 401/60 KX | transparent transparent | 59[1] 59[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 460 %[3] 460 %[3] | 25 N/mm[4] 25 N/mm[4] | 25 %[5] 25 %[5] | Lebensmittelkontakt, hohe Fellfestigkeit | |

| ELASTOSIL® R 401/60 S | transparent transparent | 60[1] 60[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 550 %[3] 550 %[3] | 26 N/mm[4] 26 N/mm[4] | 16 %[5] 16 %[5] | Lebensmittelkontakt, Standard | |

| ELASTOSIL® R 401/70 S | transparent transparent | 70[1] 70[1] | 11.3 N/mm²[2] 11.3 N/mm²[2] | 530 %[3] 530 %[3] | 31 N/mm[4] 31 N/mm[4] | 22 %[5] 22 %[5] | Lebensmittelkontakt, Standard | |

| ELASTOSIL® R 510/60 S | translucent translucent | 60[1] 60[1] | 10.2 N/mm²[2] 10.2 N/mm²[2] | 400 %[3] 400 %[3] | 22 N/mm[4] 22 N/mm[4] | 31 %[6] 31 %[6] | hitzebeständig, Standard | |

| ELASTOSIL® R 510/70 S | translucent translucent | 70[1] 70[1] | 9.4 N/mm²[2] 9.4 N/mm²[2] | 340 %[3] 340 %[3] | 21 N/mm[4] 21 N/mm[4] | 48 %[6] 48 %[6] | hitzebeständig, Standard | |

[1] Härte Shore A | DIN ISO 48-4, [2] Reißfestigkeit | ISO 37 Type 1, [3] Reißdehnung | ISO 37 Type 1, [4] Weiterreißwiderstand | ASTM D 624 B, [5] Druckverformungsrest | 22 h | 175 °C | DIN ISO 815-1 Typ B Methode A | post-cured 4 h / 200 °C, [6] Druckverformungsrest | 22 h | 175 °C | DIN ISO 815-1 Typ B Methode A, [] Geeignet, [] Gut geeignet, [] Ideal geeignet

Benefits

- High heat resistance to 300 °C

- Very good resistance to temperatures of 180 °C over very long periods

- High tear strength

- Excellent UV resistance

- High color and design flexibility

- Excellent mechanical strength

- No toxic products released in the event of fire (flame resistant)

Produktempfehlungen

Für Ihre Filterkriterien und das gewählte Land sind leider keine Ergebnisse verfügbar. Bitte kontaktieren Sie unseren Vertrieb.

|

Produkte

|

Technische Daten

|

Produktmerkmale

|

||||||

|---|---|---|---|---|---|---|---|---|

| Aussehen | Härte Shore A | Reißfestigkeit | Reißdehnung | Weiterreißwiderstand | Druckverformungsrest | Spezifische Merkmale | ||

| ELASTOSIL® R 401/60 KX | transparent transparent | 59[1] 59[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 460 %[3] 460 %[3] | 25 N/mm[4] 25 N/mm[4] | 25 %[5] 25 %[5] | Lebensmittelkontakt, hohe Fellfestigkeit | |

| ELASTOSIL® R 401/60 S | transparent transparent | 60[1] 60[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 550 %[3] 550 %[3] | 26 N/mm[4] 26 N/mm[4] | 16 %[5] 16 %[5] | Lebensmittelkontakt, Standard | |

| ELASTOSIL® R 401/70 S | transparent transparent | 70[1] 70[1] | 11.3 N/mm²[2] 11.3 N/mm²[2] | 530 %[3] 530 %[3] | 31 N/mm[4] 31 N/mm[4] | 22 %[5] 22 %[5] | Lebensmittelkontakt, Standard | |

| ELASTOSIL® R 510/60 S | translucent translucent | 60[1] 60[1] | 10.2 N/mm²[2] 10.2 N/mm²[2] | 400 %[3] 400 %[3] | 22 N/mm[4] 22 N/mm[4] | 31 %[6] 31 %[6] | hitzebeständig, Standard | |

| ELASTOSIL® R 510/70 S | translucent translucent | 70[1] 70[1] | 9.4 N/mm²[2] 9.4 N/mm²[2] | 340 %[3] 340 %[3] | 21 N/mm[4] 21 N/mm[4] | 48 %[6] 48 %[6] | hitzebeständig, Standard | |

[1] Härte Shore A | DIN ISO 48-4, [2] Reißfestigkeit | ISO 37 Type 1, [3] Reißdehnung | ISO 37 Type 1, [4] Weiterreißwiderstand | ASTM D 624 B, [5] Druckverformungsrest | 22 h | 175 °C | DIN ISO 815-1 Typ B Methode A | post-cured 4 h / 200 °C, [6] Druckverformungsrest | 22 h | 175 °C | DIN ISO 815-1 Typ B Methode A, [] Geeignet, [] Gut geeignet, [] Ideal geeignet

Benefits

- High heat resistance to 250 °C over long periods and briefly to 300 °C

- High tear strength prevents damage to ignition cables during repair or due to sharp edges in the engine compartment.

- Extremely high resistance to cyclic, thermal stress

- Excellent mechanical and chemical resistance

- Highly insulating

Applications

- Ignition cables

- Battery cables

- Power lines

Produktempfehlungen

Für Ihre Filterkriterien und das gewählte Land sind leider keine Ergebnisse verfügbar. Bitte kontaktieren Sie unseren Vertrieb.

|

Produkte

|

Technische Daten

|

Produktmerkmale

|

|||||||

|---|---|---|---|---|---|---|---|---|---|

| Appearance | Aussehen | Härte Shore A | Reißfestigkeit | Reißdehnung | Weiterreißwiderstand | Druckverformungsrest | Spezifische Merkmale | ||

| ELASTOSIL® R 401/60 KX | transparent transparent | - - | 59[1] 59[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 460 %[3] 460 %[3] | 25 N/mm[4] 25 N/mm[4] | 25 %[5] 25 %[5] | Lebensmittelkontakt, hohe Fellfestigkeit | |

| ELASTOSIL® R 401/60 S | - - | transparent transparent | 60[1] 60[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 550 %[3] 550 %[3] | 26 N/mm[4] 26 N/mm[4] | 16 %[5] 16 %[5] | Lebensmittelkontakt, Standard | |

| ELASTOSIL® R 401/70 S | - - | transparent transparent | 70[1] 70[1] | 11.3 N/mm²[2] 11.3 N/mm²[2] | 530 %[3] 530 %[3] | 31 N/mm[4] 31 N/mm[4] | 22 %[5] 22 %[5] | Lebensmittelkontakt, Standard | |

| ELASTOSIL® R 420/60 S | - - | transparent transparent | 62[1] 62[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 660 %[3] 660 %[3] | 43 N/mm[4] 43 N/mm[4] | 25 %[5] 25 %[5] | Lebensmittelkontakt, hoch weiterreissfest | |

| ELASTOSIL® R 420/70 S | - - | transparent transparent | 72[1] 72[1] | 10.0 N/mm²[2] 10.0 N/mm²[2] | 570 %[3] 570 %[3] | 45 N/mm[4] 45 N/mm[4] | 38 %[5] 38 %[5] | Lebensmittelkontakt, hoch weiterreissfest | |

| ELASTOSIL® R 510/60 S | - - | translucent translucent | 60[1] 60[1] | 10.2 N/mm²[2] 10.2 N/mm²[2] | 400 %[3] 400 %[3] | 22 N/mm[4] 22 N/mm[4] | 31 %[6] 31 %[6] | hitzebeständig, Standard | |

| ELASTOSIL® R 510/70 S | - - | translucent translucent | 70[1] 70[1] | 9.4 N/mm²[2] 9.4 N/mm²[2] | 340 %[3] 340 %[3] | 21 N/mm[4] 21 N/mm[4] | 48 %[6] 48 %[6] | hitzebeständig, Standard | |

| ELASTOSIL® R 570/70 OH | - - | black black | 71[1] 71[1] | 7.4 N/mm²[2] 7.4 N/mm²[2] | 180 %[3] 180 %[3] | 13 N/mm[4] 13 N/mm[4] | 29 %[5] 29 %[5] | elektrisch leitfähig | |

| ELASTOSIL® R 573/50 A/B | - - | black black | 50[1] 50[1] | 5.5 N/mm²[2] 5.5 N/mm²[2] | 340 %[3] 340 %[3] | 13 N/mm[4] 13 N/mm[4] | 30 %[7] 30 %[7] | elektrisch leitfähig, zweikomponentig, Additionsvernetzend | |

| ELASTOSIL® R 573/70 A/B | - - | black black | 71[1] 71[1] | 6.2 N/mm²[2] 6.2 N/mm²[2] | 246 %[3] 246 %[3] | 14 N/mm[4] 14 N/mm[4] | 29 %[7] 29 %[7] | elektrisch leitfähig, zweikomponentig, Additionsvernetzend | |

| ELASTOSIL® R plus 4305/70 | - - | transparent transparent | 70[1] 70[1] | 9.1 N/mm²[2] 9.1 N/mm²[2] | 600 %[3] 600 %[3] | 39 N/mm[4] 39 N/mm[4] | 14 %[5] 14 %[5] | zweikomponentig, Lebensmittelkontakt, niedriger Druckverformungsrest, Additionsvernetzend | |

| ELASTOSIL® R plus 4305/80 | - - | transparent transparent | 80[1] 80[1] | 7.8 N/mm²[2] 7.8 N/mm²[2] | 310 %[3] 310 %[3] | 21 N/mm[4] 21 N/mm[4] | 17 %[5] 17 %[5] | zweikomponentig, Lebensmittelkontakt, niedriger Druckverformungsrest, Additionsvernetzend | |

| ELASTOSIL® R plus 5305/70 | - - | transparent transparent | 70[1] 70[1] | 9.2 N/mm²[2] 9.2 N/mm²[2] | 590 %[3] 590 %[3] | 42 N/mm[4] 42 N/mm[4] | 10 %[5] 10 %[5] | zweikomponentig, Additionsvernetzend | |

[1] Härte Shore A | DIN ISO 48-4, [2] Reißfestigkeit | ISO 37 Type 1, [3] Reißdehnung | ISO 37 Type 1, [4] Weiterreißwiderstand | ASTM D 624 B, [5] Druckverformungsrest | 22 h | 175 °C | DIN ISO 815-1 Typ B Methode A | post-cured 4 h / 200 °C, [6] Druckverformungsrest | 22 h | 175 °C | DIN ISO 815-1 Typ B Methode A, [7] Druckverformungsrest | 22 h | 175 °C | DIN ISO 815-1 Typ B Methode A | post-cured 0.5 h / 200 °C, [] Geeignet, [] Gut geeignet, [] Ideal geeignet

Find out more about our battery and hybrid cables under “E-Mobility”.

Battery and hybrid cables in E-mobilityProduktempfehlungen

Für Ihre Filterkriterien und das gewählte Land sind leider keine Ergebnisse verfügbar. Bitte kontaktieren Sie unseren Vertrieb.

|

Produkte

|

Technische Daten

|

Produktmerkmale

|

||||||

|---|---|---|---|---|---|---|---|---|

| Aussehen | Härte Shore A | Reißfestigkeit | Reißdehnung | Weiterreißwiderstand | Druckverformungsrest | Spezifische Merkmale | ||

| ELASTOSIL® R 401/60 KX | transparent transparent | 59[1] 59[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 460 %[3] 460 %[3] | 25 N/mm[4] 25 N/mm[4] | 25 %[5] 25 %[5] | Lebensmittelkontakt, hohe Fellfestigkeit | |

| ELASTOSIL® R 401/60 S | transparent transparent | 60[1] 60[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 550 %[3] 550 %[3] | 26 N/mm[4] 26 N/mm[4] | 16 %[5] 16 %[5] | Lebensmittelkontakt, Standard | |

| ELASTOSIL® R 401/70 S | transparent transparent | 70[1] 70[1] | 11.3 N/mm²[2] 11.3 N/mm²[2] | 530 %[3] 530 %[3] | 31 N/mm[4] 31 N/mm[4] | 22 %[5] 22 %[5] | Lebensmittelkontakt, Standard | |

| ELASTOSIL® R 420/60 S | transparent transparent | 62[1] 62[1] | 11.0 N/mm²[2] 11.0 N/mm²[2] | 660 %[3] 660 %[3] | 43 N/mm[4] 43 N/mm[4] | 25 %[5] 25 %[5] | Lebensmittelkontakt, hoch weiterreissfest | |

| ELASTOSIL® R 420/70 S | transparent transparent | 72[1] 72[1] | 10.0 N/mm²[2] 10.0 N/mm²[2] | 570 %[3] 570 %[3] | 45 N/mm[4] 45 N/mm[4] | 38 %[5] 38 %[5] | Lebensmittelkontakt, hoch weiterreissfest | |

| ELASTOSIL® R plus 4305/70 | transparent transparent | 70[1] 70[1] | 9.1 N/mm²[2] 9.1 N/mm²[2] | 600 %[3] 600 %[3] | 39 N/mm[4] 39 N/mm[4] | 14 %[5] 14 %[5] | zweikomponentig, Lebensmittelkontakt, niedriger Druckverformungsrest, Additionsvernetzend | |

| ELASTOSIL® R plus 4305/80 | transparent transparent | 80[1] 80[1] | 7.8 N/mm²[2] 7.8 N/mm²[2] | 310 %[3] 310 %[3] | 21 N/mm[4] 21 N/mm[4] | 17 %[5] 17 %[5] | zweikomponentig, Lebensmittelkontakt, niedriger Druckverformungsrest, Additionsvernetzend | |

| ELASTOSIL® R plus 5305/70 | transparent transparent | 70[1] 70[1] | 9.2 N/mm²[2] 9.2 N/mm²[2] | 590 %[3] 590 %[3] | 42 N/mm[4] 42 N/mm[4] | 10 %[5] 10 %[5] | zweikomponentig, Additionsvernetzend | |

[1] Härte Shore A | DIN ISO 48-4, [2] Reißfestigkeit | ISO 37 Type 1, [3] Reißdehnung | ISO 37 Type 1, [4] Weiterreißwiderstand | ASTM D 624 B, [5] Druckverformungsrest | 22 h | 175 °C | DIN ISO 815-1 Typ B Methode A | post-cured 4 h / 200 °C, [] Geeignet, [] Gut geeignet, [] Ideal geeignet