Press Photos

Please note our terms of use governing the use of press images. By downloading images from our media database, you agree to these terms of use:

Press images may only be used for press purposes (print, electronic media, online) and may not be edited. Indicating the picture credits (source: Wacker Chemie AG) is obligatory. Images deleted from the media database may no longer be used in future. If a press image is used, please provide us with a copy or link. In other respects, the following copyright information shall apply: www.wacker.com/disclaimer

Category

Reset perimeterBurghausen - Historic Spraydryer

The first spray dryer for VINNAPAS® polymer powders went on stream at WACKER’s parent plant in Burghausen in 1957. The facility produced 1,200 metric tons per year. To date, over 1 million metric tons of powder have been sold, and in summer 2007, WACKER Burghausen will commission the world’s largest plant with an annual capacity of 30,000 tons.

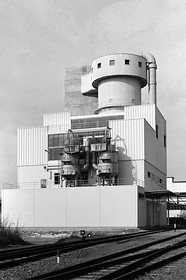

Order photoBurghausen - Spray-drying towers

Spray-drying towers for dispersible polymer powders at WACKER’s parent plant in Burghausen, Germany. With the construction of a new 50,000-metric-ton spray dryer, WACKER is strengthening its position as a market and technology leader in this field.

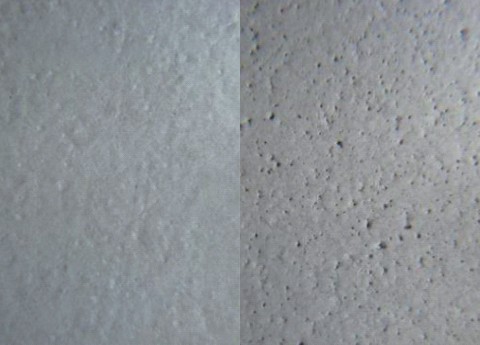

Order photoVINNAPAS® Surface

Self-leveling flooring and troweling compounds modified with VINNAPAS® produce an extraordinarily smooth, even and fine pored surface (left), as opposed to formulations without or with conventional binders (right). Even a small amount of VINNAPAS® significantly enhances abrasion resistance, tensile strength in bending as well as compressive strength and provides crack-free setting

Order photoVINNAPAS® SLC test

An applications engineer in Burghausen tests the spreading and leveling properties of polymer-modified flooring compounds. Self-leveling flooring compounds and underlayments containing VINNAPAS® produce very smooth and crater-free surfaces characterized by flexibility, good adhesion to all substrates and crack-free hardening. The surface is abrasion resistant, load resistant and can be walked on soon after installation.

Order photoCyclodextrins Wall Sample

Taking a sample from a wall treated with a coating containing cyclodextrin fragrance complexes. By molecular inclusion in cyclodextrin, for the first time, essential oils and other fragrances can be used in plasters, paints and other coatings.

Order photo