Our system has noticed that you are based in , but the current country setting is . Do you still want to change your country?

- Home

- Products & Services

- Applications

- Construction Materials

- Boards & Panels

Boards & Panels

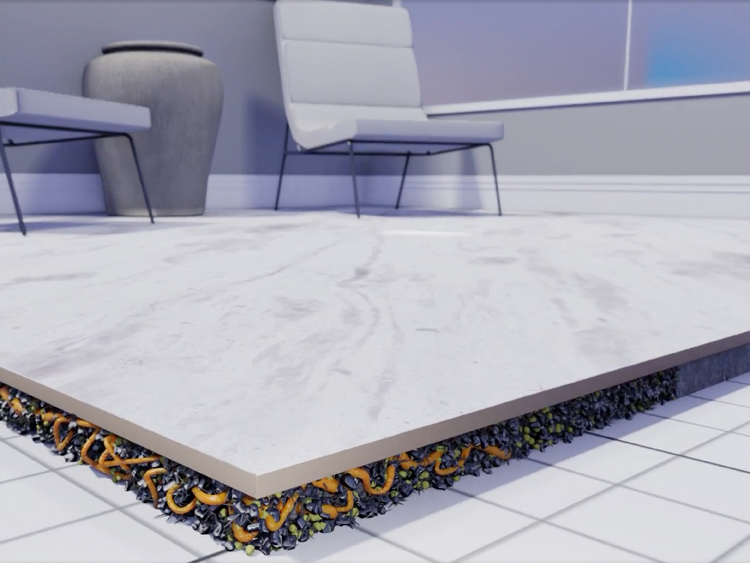

Building with gypsum and fiber cement boards is fast and flexible. To additionally ensure a high quality standard, VINNAPAS® polymer binders are used to enhance the characteristics of mortars, plasters and joint fillers in these applications. SILRES® BS silicone resins are ideal for hydrophobization.

Thanks to its favorable carbon footprint, gypsum contributes significantly to sustainable construction. However, gypsum is water-soluble. VINNAPAS® dispersible polymer powders and SILRES® BS products help to compensate for this disadvantage.

Cement fiber boards, backer boards and fire-resistant boards are treated with SILRES® BS products to reduce the capillary water absorption by post- or bulk-impregnation.

Benefits

- Increased freeze/thaw resistance

- Better dimensional stability in wet areas

- Prevention of premature drying of plasters, mortars and tile adhesives through optimal water retention

- Reduced water absorption of lightweight fillers

- Prevention of additional water ingress at cut edges by integral hydrophobization

- No paint peeling (siloxane used as primer)

Product Recommendations

Sorry, no results are available for your filter criteria and selected country. Please contact one of our sales offices.

|

Products

|

Technical data

|

Suitability

|

|||

|---|---|---|---|---|---|

| Viscosity, kinematic | Appearance |

Boards & Panels

|

Fiber Cement Boards

|

||

| SILRES BS 17040 US | - - | - - | - | - | |

| SILRES BS 17040 US | - - | - - | - | - | |

| SILRES BS 1705 BR | - - | - - | - | - | |

| SILRES® BS 1603 CN | 130 - 300 mm²/s[1] 130 - 300 mm²/s[1] | clear, colorless to slightly yellow[2] clear, colorless to slightly yellow[2] | - | - | |

| SILRES® BS 1701 | - - | - - | - | - | |

| SILRES® BS 1703 SQ | 130 - 300 mm²/s[1] 130 - 300 mm²/s[1] | clear, colorless to slightly yellow[2] clear, colorless to slightly yellow[2] | |||

| SILRES® BS 1705 | - - | - - | - | - | |

| SILRES® BS 3003 | - - | - - | - | - | |

[1] Viscosity, kinematic | DIN 51562-1 , [2] Appearance and color, [] Suited, [] Well suited, [] Ideally suited

To improve the poor moisture resistance of gypsum, SILRES® BS polymethylhydrosiloxane emulsions can be used for water-repellent treatment. Thanks to the chemical interaction between the gypsum crystals and the silicone, these materials provide far more efficient protection than organic water repellents.

Enhancing wallboard:

Used as admixture with significant benefits over wax additives (for all wallboard plants)

Enhancing fiberboards:

Surface treatment with excellent hydrophobic properties

Product Recommendations

Sorry, no results are available for your filter criteria and selected country. Please contact one of our sales offices.

|

Products

|

Technical data

|

Suitability

|

|||

|---|---|---|---|---|---|

| Refractive index | Appearance |

Boards & Panels

|

Gypsum Wallboards and Gypsum Fiberboards

|

||

| SILRES BS 2410 A | - - | - - | |||

| SILRES® BS 16 | - - | - - | - | - | |

| SILRES® BS 94 | approx. 1.396 approx. 1.396 | colorless liquid colorless liquid | - | - | |

[] Suited, [] Well suited, [] Ideally suited

VINNAPAS® dispersible polymer powders are used as binders in gypsum plasters and fillers to improve manual and machine processing, reduce the water uptake and increase the flexibility, making for smooth, crack-free surfaces. Grades without plasticizers support the formulation of low-emission end products.

Benefits

- Outstanding tensile adhesive strength on gypsum plasterboard and jointing tapes

- Excellent workability

- Particularly smooth, level surface devoid of cracks or crevices

- Reduced water uptake

- Plasticizer-free products available

Reduction in the Water Absorption of a Gypsum Joint Filler

Between x and y weight percent SILRES® BS POWDER G is added to a commercially available gypsum joint filler (left-hand bar). The test specimens obtained were then immersed in water for two hours. The chart shows how much water by weight percent was absorbed by the test specimens.

SILRES® POWDER G is an additive for waterproofing gypsum-based dry-mix mortars. It is an active substance in solid form and low in volatile organic compounds. SILRES® POWDER G can reduce the water absorption of gypsum powder products by more than 90% applying a dosage rate of 0.5 weight percent.

Benefits

- Good water-repellency

- Easy handling and storage

Product Recommendations

Sorry, no results are available for your filter criteria and selected country. Please contact one of our sales offices.

|

Products

|

Technical data

|

Product properties

|

Suitability

|

|

|---|---|---|---|---|

| Minimum film forming temperature | Specific Features |

Wall and Joint Fillers

|

||

| SILRES® POWDER G | - - | - | ||

| VINNAPAS® 4023 N (GER) | 1 °C[1] 33.8 °F[1] | - | ||

| VINNAPAS® 4115 N (GER) | 4 °C[1] 39.2 °F[1] | - | - | |

| VINNAPAS® 4121 N | 1 °C[1] 33.8 °F[1] | - | - | |

| VINNAPAS® 5005 N | 11 °C[1] 51.8 °F[1] | - | - | |

| VINNAPAS® 5010 N (CTY) | 4 °C[1] 39.2 °F[1] | - | ||

| VINNAPAS® 5010 N (GER) | 4 °C[1] 39.2 °F[1] | - | ||

| VINNAPAS® 5012 T | 4 °C[1] 39.2 °F[1] | - | ||

| VINNAPAS® 5028 E (CTY) | 4 °C[1] 39.2 °F[1] | - | ||

| VINNAPAS® 5710 N (GER) (Scale-up Product) | 4 °C[1] 39.2 °F[1] | - | ||

| VINNAPAS® 7031 H | 0 °C[1] 32.0 °F[1] | Hydrophobic | - |

[1] Minimum film forming temperature | DIN ISO 2115, [] Suited, [] Well suited, [] Ideally suited