This content is for United Kingdom. Our system has detected that you are from United States. Do you want to set United States as your new country?

GENIOSIL® STP-E10

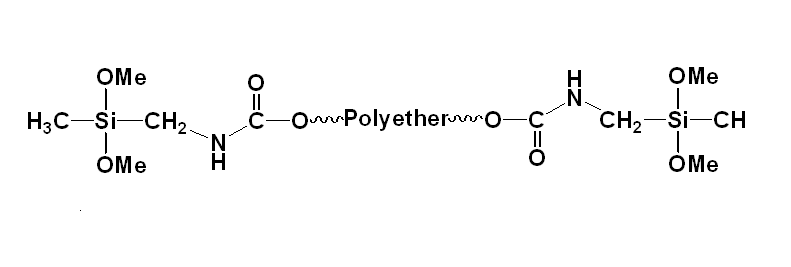

GENIOSIL® STP-E10 is a polyether-based silane-terminated polymer suitable as a binder in moisture curing formulations. It is a clear liquid with a slight but characteristic odor and differs to conventional silylated polymers due to its high reactivity. This is a direct consequence of the structural proximity of the nitrogen atom to the silicon atom in the dimethoxy(methyl)silyl-methylcarbamate group (alpha-effect). It hydrolyzes in the presence of moisture to finally form a stable siloxane network initiated by mild catalysis as opposed to heavy metal ions.

- CAS No. 611222-18-5

Properties

Formulations based on GENIOSIL® STP-E10 are characterized by the following advantages:

- simple compounding with conventional auxiliaries

- plasticizer free if desirable

- tin free

- transparent systems

- good mechanics

- rapid curing

- broad adhesion profile

- long shelf life

Specific features of GENIOSIL® STP-E10

- Broad adhesion profile

- Good mechanics

- Isocyanate-free

- Low viscosity

- Non-labeling

- Polymer designed for low-modulus transparent formulation

- Solvent-free

- Tin-free catalysis

Data sheets

Application:

GENIOSIL® STP-E10 is used as a reactive binder for sealants and adhesives, potting compounds and coatings. Curing takes places at ambient temperature in the presence of both moisture and catalyst. Depending on the formulation, either prepared as one-part or two-part systems, shows good adhesion to a wide variety of substrates even without pretreatment. The low glass transition temperature allows stable mechanical properties over a wide temperature range.

Processing:

GENIOSIL® STP-E10dissolves readily in standard organic solvents. It is virtually insoluble in aqueous media, and reacts slowly releasing methanol and forming a resinous deposit. Despite its highly reactive terminal groups, uncatalyzed GENIOSIL® STP-E10 is stable in air for several days. However, its reactivity with water or atmospheric humidity must be taken into account during storage and processing, since the material will slowly start to condense. GENIOSIL® STP-E10 can be formulated by conventional methods and mixing processes. Its formulation composition depends on the required property profile.

GENIOSIL® STP-E10 can be formulated with a variety of fillers. The range starts with oxides, such as aluminum hydroxide, quartz powders or pyrogenic silica, and extends to coated and uncoated chalks. The type and amount depends on the mechanical needs as well the desired thixotropy.

Water scavengers can be added to stabilize the formulations against premature curing as this is moisture-curing technology. Therefore exclusion of moisture during compounding and storage is necessary. GENIOSIL® XL 10 or GENIOSIL® XL 70 are particularly suitable scavengers.

Any kind of plasticizer can be used to further lower the viscosity as well as to impact elongation values. It has been observed, that polypropylene glycol types give better mechanical performance whereas aromatic plasticizers like trimellitates or phthalates yield good adhesion values.

Antioxidants, UV- and light-stabilizers are mandatory to ensure durable sealants and adhesives. The amount and kind of stabilizer depends on application needs.

Curing of GENIOSIL® STP-E10 requires a catalyst that does not necessarily have to be organo-metallic. However dioctyl tin may be used if required. Catalysis can also be accelerated with titanium compounds, as well as inorganic (phosphoric) or organic (tartaric) acids.

Primarily, we recommend using an amine catalyst, and adjusting the skin-formation time by varying the amount of aminosilane used. GENIOSIL® GF 9 and GENIOSIL® GF 95 have proven particularly advantageous here. In particular, GENIOSIL® GF 95 can attain improved water resistance, which is further increased by the addition of epoxy silanes.

Surface Treatment:

Always apply the formulation to clean and dry surfaces.

Packaging

Storage

Sales and support

Bracknell RG12 1WA

United Kingdom

How can we help you?

- Do you need help in choosing a product or do you require technical support? If so, please contact our experts.