50% decrease in greenhouse gases by 2030

Net-zero by 2045

15% reduction in specific water withdrawal by 2030

25% drop in emissions relating to upstream products by 2030

15% drop in specific energy consumption by 2030

We Lead the Way.

WACKER is setting itself new, ambitious goals to achieve net-zero in 2045. The new goals to cut greenhouse gases are science-based targets. In other words, they are consistent with the goal of keeping the global rise in temperature below 1.5 degrees Celsius and therefore comply with the Paris Agreement. WACKER has joined Race to Zero, the UN’s carbon neutrality initiative. We are thus voluntarily committing to the 1.5-degree target and undertaking to issue transparent progress reports on our course toward net-zero.

2030 is a key milestone on our way to meeting this goal. That’s why we’ve set ourselves even more ambitious sustainable development goals:

WACKER Products to Combat Climate Change

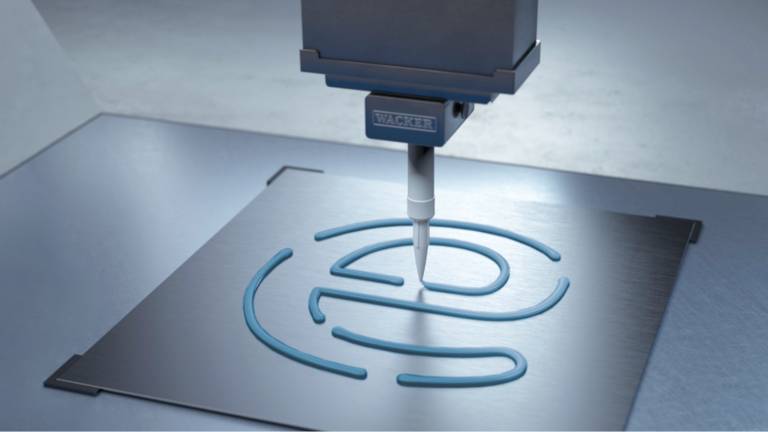

Thermally Conductive Specialty Silicones for Electric Vehicles

Most experts agree that the next generation of cars will be electric. The advancement of electromobility is at the top of the automotive industry’s agenda. Various obstacles need to be overcome, however, before electric cars can be mass-produced. A key aspect is how to protect sensitive automotive electronics from overheating.

Dispersible Polymer Powders for Wall Paints

Thanks to their low weight and space-saving packaging, polymer binders for wall paints in powder form reduce CO2 emissions during shipment.

WACKER City

Visit our WACKER City and set off on an exciting journey of discovery. Our products can be found in solar modules, cars and building materials, not to mention a great many everyday objects and consumer goods. Take a stroll through the multifaceted world of WACKER’s sustainable solutions.

Dispersions and Dispersible Polymer Powders in Thermal Insulation Systems for Buildings

WACKER and Dubai Municipality demonstrate energy-saving, internationally standardized construction technologies in action with two model houses.

Polysilicon, the Most Important Raw Material for Solar Modules

Quartz is the starting material for the production of hyperpure polysilicon, the most important raw material for photovoltaics. Between quartz and hyperpure polysilicon lie not only a number of highly complex working steps that are, technically speaking, extremely sophisticated – but also, in the case of WACKER,…

Certified Alternative

In VINNAPAS® eco dispersible polymer powders, WACKER is now offering polymers that are based on acetic acid derived from wood waste.

The Silicone Sealant That Conserves Fossil Resources

With ELASTOSIL® eco, sustainable building is possible across the entire life cycle – from production right up to the finished building.

Adhesives Are What Make Wind Power Possible

the rotor blades – as much as 80 meters long in newer on-shore wind turbines – consist of two half-shells bonded firmly together with reinforcement elements, known as shear webs. These adhesive bonds are capable of transmitting the powerful forces that arise during turbine operation.

Specific Measures and Projects by 2030

Silicon Metal

WACKER is adopting specific projects and measures to meet its new goals. For instance, the company is performing feasibility studies on the extent to which its Norwegian site in Holla can substitute sustainably generated charcoal for the coal currently used in silicon-metal production there. WACKER sees such a move as an important lever in significantly lowering its carbon footprint. Other options available to the company so as to achieve even more sustainable silicon-metal manufacturing processes include the use and storage of carbon and the increased use of hydroelectric and wind power in order to meet the site’s electricity demand.

Silicon metal is a key raw material for producing silicones and for polysilicon, which is used to make solar cells and semiconductor devices. The quantities produced in Holla cover roughly a third of WACKER’s annual demand.

Electrification

WACKER regards the systematic electrification of its production processes as essential if further progress is to be made in the decarbonization of its manufacturing base. We are already in a very good starting position in this respect. 60 percent of WACKER’s production processes are already electrified – a much higher figure than in many other chemical companies.

“As one of the world’s leading manufacturers of specialty chemicals and polysilicon, we play a major role in the energy transition and in reducing the impact of climate change. Products that enable our customers to bring climate-friendly and resource-efficient products onto the market already make up about two thirds of our portfolio. In the coming years, we intend to significantly expand our portfolio of particularly sustainable products, and make considerable efforts to defossilize our production. We consider that this holds significant potential for our business success.”

Dr. Christian Hartel, President & CEO of Wacker Chemie AG

Our sustainability strategy in detailPolitical communication at WACKER

As a globally active company, WACKER is part of society and contributes to sustainable solutions for the challenges of our time. In doing so, we maintain regular contact with various stakeholders - including politicians.

Regarding our involvement in the political arena, we have formulated binding rules in line with our corporate governance. WACKER Communications' political communication follows ethical principles and is subject to both legal regulations and internal specifications. It forms an integral part of responsible corporate management.

Sustainability library

Non-Financial Statement (Facts & Figures)

Responsible Care

(PDF 356.7 KB)

Global Compact

Sustainability Factsheet: Supply Chains

(PDF 216.2 KB) - english

Whistleblower Hotline

Certificates

Sustainability Factsheet: Sustainable Products

(PDF 389.6 KB) - english

Sustainability Factsheet: The Sustainable Development Goals (SDGs)

(PDF 265.3 KB) - english

WACKER Tax Policy

(PDF 158.4 KB)

Factsheet Sustainability: Strategy and Roadmap

(PDF 2.2 MB) - english

Sustainability Factsheet: Climate Protection

(PDF 220.2 KB) - english

Circular Economy Fact Sheet 2023

(PDF 524.2 KB) - english

Sustainability Factsheet: Life Cycle Assessment (LCA)

(PDF 123.3 KB) - english

The Mass Balance Approach at WACKER

(PDF 486.8 KB) - english

CDP Climate Change 2024 - Questionnaire

(PDF 2.0 MB) - English

Sustainability Factsheet: Integrated Production

(PDF 113.8 KB) - english

Sustainability Factsheet: Energy Management

(PDF 332.5 KB) - english

Sustainability Fact Sheet Waste Management

(PDF 413.9 KB) - english

Sustainability Factsheet: Water Management

(PDF 1.8 MB) - english

Sustainability Factsheet: Light Emissions

(PDF 347.3 KB) - english

Our Position on REACH

Policy: Environment & Energy, Health, Safety & Product Safety

(PDF 1.5 MB) - English

Code of Conduct

Supplier Code of Conduct

MSA Statement

(PDF 133.5 KB)

Sustainability Factsheet: Employee and Human Rights

(PDF 139.3 KB) - english

Sustainability Factsheet: Animal Welfare

(PDF 85.3 KB) - english

WACKER's Position on "Conflict Minerals"

(PDF 166.9 KB) - english

Sustainability Factsheet: Supply Chains

(PDF 216.2 KB) - english

You’d like to find out more?

Contact

We would be happy to assist you with any questions you may have concerning sustainability at WACKER.

Send a message