Our History

Join us on a journey through over 100 years of history. A success story from 1914 to the present day – with groundbreaking innovations and pioneering ideas to forge ahead in the 21st century.

“Net Zero by 2045” target validated

Geared toward the 1.5 °C goal stipulated in the Paris Agreement, WACKER’s climate strategy has been endorsed by the Science Based Targets initiative (SBTi). This makes WACKER one of the first chemical companies worldwide with a validated net zero target.

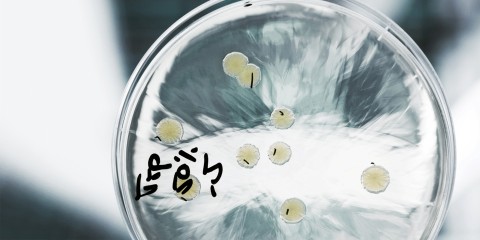

WACKER opens mRNA Competence Center in Halle, Germany

At its biotech site in Halle, Germany, WACKER opened an mRNA competence center to produce mRNA actives on a large scale. Some of the site’s capacities aid the German government in making vaccines available as part of its pandemic-preparedness plan.

WACKER House opens its doors

WACKER opened its new company headquarters, WACKER House, in Munich’s Werksviertel district. The ambiance of the modern, sustainable building supports flexible working models, creativity and innovation across five floors, offering employees an inspiring work environment geared toward the needs of the future.

Groundbreaking ceremony in the Czech Republic

WACKER launched the construction of a new plant in the Czech town of Karlovy Vary. The plant produces specialty silicone products aligned with megatrends such as the energy transition, e-mobility and health. Hundreds of millions of euros have been invested in the project. Operations are expected to commence in late 2025, with some 200 new jobs to be created by 2028.

Anniversary:

30 years of WACKER in China

Along with business partners and government representatives, WACKER celebrated the 30-year anniversary of its subsidiary in China. What began as sales offices has long since developed into an extensive network of production, research and service sites. WACKER now employs a staff of around 1,700 in China.

75 years of silicones

From pioneering silicone development in Europe to becoming the world's second largest manufacturer of silicone products today:

WACKER purchases ADL BioPharma

WACKER strengthened its biotechnology business through the acquisition of this Spanish CMO for the foods, pharmaceuticals and consumer goods industries. ADL BioPharma employs 300 people and offers roughly 2,000 cubic meters of additional fermentation capacity. The purchase set the stage for further growth.

New production facility in India

WACKER opened a production site in Panagarh, India, for manufacturing silicone rubber and silicone rubber compounds for electromobility, medical engineering and electricity supply applications. Part of the Group’s new growth strategy, the site will give rise to some 100 new jobs during the first expansion phase.

New competence center for mRNA active ingredients in Halle

A symbolic ground-breaking ceremony launched the construction of our Technical Competence Center for mRNA actives in Halle. At the Weinberg Campus, four production lines were initiated for active ingredients based on mRNA, such as coronavirus vaccines. Production capacity in Halle will more than triple, and the number of employees will more than double. WACKER has invested more than 100 million euros in these projects.

Sustainable development goals

WACKER presented its new, ambitious sustainable development goals. Not only will the company select sustainable suppliers for its raw-material procurement, it will also make its consumption of energy and water even more efficient. WACKER continues to invest in expanding its portfolio of specialty products. These help our customers market climate-friendly and resource-saving solutions. WACKER Sustainable Solutions manages the product portfolio in line with defined sustainability criteria. By 2030, WACKER’s entire portfolio is to meet these criteria and greenhouse gas emissions are to be halved, regardless of volume growth. The company intends to achieve net zero by 2045.

WACKER Sustainable Solutions

New Production Facility in China

WACKER acquired a 60-percent stake in SICO Performance Material Co., Ltd., a specialty silane manufacturer. Based in Jining, China, SICO is a leading producer of organofunctional silanes for high-performance adhesives, sealants, coatings and composite materials. This acquisition sees WACKER further expanding its portfolio of high-quality specialty products in Asia.

Expansion of biopharma operations

WACKER expanded its influence on the biopharma market through the acquisition of pharmaceutical contract manufacturer Genopsis Inc. Renamed Wacker Biotech US Inc., the company produces pDNA for innovative therapeutic agents, including nucleic acid-based gene therapies and vaccines.

Changes to the Executive Board

Dr. Christian Hartel was designated Wacker Chemie AG’s new president and CEO effective May 2021, succeeding Dr. Rudolf Staudigl, who retired at the end of the Annual Shareholders’ Meeting. Angela Wörl was appointed to serve on the Executive Board as personnel director.

The Executive Board

Coronavirus Pandemic

WACKER played its part in the fight against the coronavirus, donating some 11,000 liters of isopropyl alcohol to make 15,000 liters of disinfectants for Bavarian hospitals and care facilities.

Charitable institutions were especially hard hit by the pandemic. WACKER’s Executive Board decided to alleviate the situation with special donations. WACKER HILFSFONDS received €100,000 for its partner schools in Nepal, Haiti and Kosgoda.

New production plants

At its site in Amsterdam, WACKER invested in production facilities for biopharmaceuticals, LMPs (live biotherapeutic products) and vaccines.

Wacker Chemie AG expanded its Chinese polymer activities by investing around US$100 million in building two new production plants at its site in Nanjing.

WACKER Global

-

2024

-

2023

-

2022

-

2021

-

2020

Expanding the site in South Korea

After a 20-month construction phase, Wacker Chemie AG started up a new spray dryer for producing dispersible polymer powders in Ulsan, South Korea. The new facility was part of the site’s ongoing expansion to increase the company’s production capacity for dispersions and dispersible polymer powders in Asia.

Research on silicon-based materials

Wacker Chemie AG intensified its research into silicon-based materials for high-performance batteries, acquiring a stake in British battery specialist Nexeon Ltd. Powerful lithium-ion batteries are vital for applications in mobile devices, such as smartphones and tablets, and in electric vehicles.

Silicon-metal production in Norway

WACKER’s site in Holla, Norway, started up a new silicon-metal production plant. The output of the new furnace, one of the largest of its kind in the world, increased the Holla site’s total capacity by more than 40 percent, enabling it to cover about one-third of WACKER’s demand at its German sites.

New production site in the Netherlands

WACKER acquired a Dutch production plant from SynCo Bio Partners Luxembourg S.à r.l. This facility produces biopharmaceuticals, probiotics and vaccines. The new Wacker Biotech B.V. subsidiary is based in Amsterdam.

WACKER BIOSOLUTIONS

WACKER BIOSOLUTIONS began producing fermentation-generated cystine at its site in León, Spain. At the same time, the division expanded its Jena site to include biologics production facilities.

Production with renewable raw materials

WACKER became the world’s first manufacturer capable of using renewable resources to produce commercial quantities not only of dispersions based on vinyl acetate-ethylene copolymer (VAE), but also of further VINNAPAS® products based on vinyl acetate.

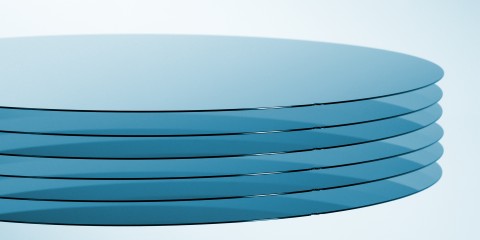

Sale of majority stake in Siltronic AG

This strategic move marked a shift in focus: WACKER would now concentrate on its chemistry and polysilicon business.

Visit from the German president

German President Frank-Walter Steinmeier visited WACKER’s Nünchritz production site during his three-day tour of the Free State of Saxony. Accompanied by Saxony’s State Governor Stanislaw Tillich, he learned about WACKER’s role as an economic player in the region, as well as about recruiting suitably qualified staff, offering training programs and maintaining a work-life balance.

Largest investment in the history of WACKER

A new production site for polysilicon started operation Charleston, Tennessee, USA. Construction took five years, at an investment of approx. $2.5 billion. This marked the peak of the expansion in polysilicon capacity, which had been growing steadily since the start of the solar boom at the turn of the century.

A world premier:

The first industrial 3D printer for silicones

The process developed by four WACKER scientists was a milestone in additive manufacturing.

IPO of Siltronic AG and the Company of the Year Award

The weekly publication ICIS Chemical Business named WACKER as its Company of the Year. The Siltronic AG IPO occurred during the same year.

One hundred years of WACKER

The company celebrated the day of its founding at an event in Munich with some 500 guests, including Bavaria’s Minister President, Horst Seehofer.

75 Years of VINNAPAS® dispersions

An anniversary exhibit in a reconverted shipping container celebrated this success over a period of 12 months, on three continents and with many events – as well as with the “75 years of VINNAPAS®dispersions” webpage.

50 Years of silicone resin emulsion paints

The discovery of these water repellent yet water-vapor-permeable paints was a truly pioneering achievement on the part of our researchers and developers. Today, SILRES®BS silicone resin emulsion paints are the standard for sustainable coating solutions.

Opening of the Shanghai Center

The opening of the new company headquarters for the China region provided a home for marketing, sales and administrative functions as well as R&D and applications laboratories.

Backward integration down to metallurgical-grade silicon

Backward integration extending all the way down to metallurgical-grade silicon: WACKER acquired the Holla metallurgical silicon site near Trondheim, Norway, where silicon that is 98.5% pure is produced from sand and coal. This is subsequently upgraded to hyperpure polycrystalline silicon with a purity level of 99.99999999% at WACKER POLYSILICON sites in Burghausen, Nünchritz and, as of 2016, in Charleston, USA.

Silicone production site

WACKER and Dow Corning joined forces to launch the world’s largest silicone production site in Zhangjiagang, China.

-

2019

-

2018

-

2017

-

2016

-

2015

-

2014

-

2013

-

2012

-

2010

Commissioning of the production plant for dispersible polymer powders in Nanjing

The Nanjing plant, which can produce 30,000 metric tons of polymer powders a year, is the largest of its kind in China. WACKER is the sole supplier of polyvinyl-acetate-based polymer dispersions and dispersible polymer powders – with production sites on all three key continents.

Manufacture of silicon wafers in Singapore

Samsung and Siltronic’s joint facility started manufacturing 300 mm wafers from hyperpure silicon in Singapore.

IPO in Frankfurt

A new era began for the WACKER Group in April 2006. Wacker Chemie AG shares were traded on the Frankfurt Stock Exchange for the first time on April 10. The IPO saw WACKER placing 14.99 million shares with institutional and private investors. At €80, the issue price was set at the upper end of the price range. Advance demand was huge. The shares issued were over-subscribed more than 18 times. Since the IPO was held, the family shareholder continues to keep its majority stake in the company.

Knowledge management for customers, partners and new employees

The VINNAPAS® ACADEMY was founded. This later became WACKER ACADEMY, which currently operates at 15 sites around the globe, providing on-site knowledge transfer about handling WACKER products and their applications.

Founding of the WACKER Relief Fund

WACKER founded a charitable organization to support victims of natural disasters with the aim providing fast, unbureaucratic aid. The main focus was on helping children by building or repairing schools or orphanages.

Construction of pilot plant for granular polysilicon

These innovative little pellets were needed for manufacturing silicon monocrystals. As they are easy to meter, they constitute a considerable improvement to the “poly chunks” used before. These serrated, irregular pieces had to be filled into the crucible by hand.

-

2009

-

2008

-

2006

-

2005

-

2004

A new site in Saxony

With the purchase of the Nünchritz plant, WACKER acquired an important new site for silicones – and created ideal conditions for the production of innovative silicone products. Over the following decade, the site was gradually expanded. Today, it is one of the three WACKER sites worldwide that produce hyperpure polycrystalline silicon.

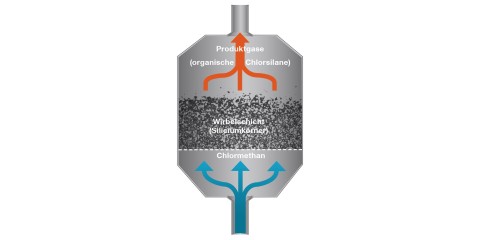

WACKER Silicone Award for the fathers of silicones

Richard Müller and Eugene Rochow were honored with the WACKER Silicone Award. Beginning in 1942 and independently of each other, both developed a direct synthesis route for dimethyldichlorosilane – the forerunner of WACKER’s over 3,000 different silane and silicone products.

WACKER moves to new headquarters

Group HQ has been based in the Neuperlach district of Munich ever since.

Production of bioengineered products begins

The inauguration of the biotechnology research center for manufacturing compounds for the pharma, food and agricultural sectors heralded the age of biotechnology.

The following years saw this field blossom at new sites in Eddyville, Jena, Halle and Léon. In 2008, WACKER’s bioengineered L-cysteine won the BDI (Federation of German Industries) Environmental Award.

-

1998

-

1992

-

1990

Founding of DRAWIN Vertriebs-GmbH

In May 1987, DRAWIN Vertriebs-GmbH was founded as a wholly owned subsidiary of Wacker Chemie AG. It took over some areas of the WACKER SILICONES business division's logistics and distribution planning. DRAWIN’s product range now includes around 1,000 different silicone products sold in over 100 countries worldwide. Its strengths are fast shipping, the flexible combination of different types and quantities of products and a wide, readily available product range.

Silicone scientists honored

The first WACKER Silicone Award was presented. To this day, the prize has continued to rank among the world’s most prestigious awards in organosilicon chemistry. It was first awarded to Prof. Peter Jutzi and Prof. Robert Auner.

Expansion of the biological wastewater treatment plant in Burghausen

Designed for a capacity of up to 300,000 inhabitants, the plant now treats wastewater from Burghausen and neighboring communities in Austria as well.

Entry into Asian markets

Wacker Chemicals East Asia Ltd. was founded in Tokyo, Japan, and a counterpart in Singapore was established a year later.

WACKER silicon conquers space

Research in zero gravity: semiconductor experiments with silicon were conducted for WACKER and Chemitronic during the Spacelab mission.

WACKER silicone rubber goes liquid

WACKER’s first RTV (room-temperature-vulcanizing) and HTV (high-temperature-vulcanizing) grades were launched in the early 1950s. These products were then continuously enhanced until a new class emerged: LSR (liquid silicone rubber).

-

1987

-

1985

-

1983

-

1980

The birth of Siltronic

Wacker Siltronic Corporation was founded in Portland, Oregon, USA, for the manufacture and sales of semiconductor raw materials. The name Siltronic was used here for the first time.

A dedicated environmental protection department established at the Burghausen plant

Comprising Emissions Control, Wastewater Management and Residual Waste Management units, the new department initiated the construction of a biological wastewater treatment plant.

‘Byproducts become bestsellers

HDK® was produced for the first time at the WACKER plant in Kempten. This pyrogenic silica was originally produced from the silanes that accumulated as byproducts of the Müller-Rochow synthesis (silanes and silicones) and Siemens processes (hyperpure polycrystalline silicon). WACKER HDK® and its range of products are among the most successful WACKER products of all time. They are used in various applications such as silicone rubber, paints, coatings, laser toner, toothpaste and ketchup.

The 1970s

Internationalization begins

WACKER established new sales offices across Europe to bring its products closer to customers. Today, the company generates 80% of its sales outside Germany.

-

1978

-

1974

-

1972

-

1970

Founding of Wacker Chemitronic Gesellschaft für Elektronik-Grundstoffe mbH

This later became Siltronic. Two new full-scale production plants with distillation columns more than 50 meters high went into operation manufacturing hyperpure polysilicon and distilling the trichlorosilane precursor.

Transition from the coal age to petrochemicals

WACKER opened its new ethylene-based vinyl acetate monomer plant. Because calcium carbide was no longer needed in Burghausen, the eight 50-meter carbide silos – Burghausen plant landmarks – were repurposed to store mainly metallurgical-grade silicon used to produce silicones and hyperpure silicon.

Successful launch on the North American market

Wacker Chemicals Corporation (WCC) was founded in New York. WCC also acquired Monosilicon, a company based in Los Angeles, where hyperpure silicon rods produced using the crucible pulling process were cut into slices – the term “wafer” had not yet been coined.

New site, new processes

At the new WACKER plant in Cologne, a facility based on the 2nd WACKER process was the first worldwide to start producing acetylaldehyde from ethylene on an industrial scale. This secured an economical raw-material base for acetic acid and its derivatives in the VINNAPAS® range.

-

1968/69

-

1965

-

1960

New facilities and buildings were erected in Burghausen, including a 19-meter-high crude silane column and a tank farm for pure and intermediate products. In the decade between 1957 and 1967, annual sales generated from silicon-based plastics increased almost fivefold to 37.8 million West German marks.

2. The WACKER Process

Basic-research scientists at WACKER based the production of acetylaldehyde and acetic acid on a new raw material. These products could now be manufactured using economical ethylene from the petrochemical industry instead of acetylene made from calcium carbide, which had become too expensive. Known in textbooks as the 2nd WACKER process, this pioneering synthesis method has been licensed all around the world.

Instant coffee inspires a bestseller

While enjoying a cup of Nescafé, Dr. Max Ivanovits came up with the idea of developing a water-free dispersible polymer powder from water-based VINNAPAS®dispersions. Powder production began in 1958; these powders gradually revolutionized the construction industry and made WACKER the world leader in this field.

First production of hyperpure silicon

Dr. Eduard Enk laid the foundation for WACKER’s semiconductor business. The first silicon rods were produced as early as 1955, with several hyperpure silicon production plants going into operation by 1961.

-

1957

-

1953

Silane and silicone research begins

Following his lecture on “Plastics Containing Silicon,” the young chemist Dr. Siegfried Nitzsche was hired on the spot. He later became the father of WACKER silicones. In 1949 Nitzsche and his colleagues were successful in synthesizing silane for the first time. Soon after, the first silane furnace was up and running.

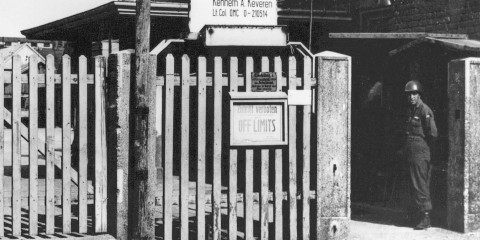

Impending closure

After the war ended, plant operations temporarily came to a halt as the Allies contemplated dismantling the company. The efforts of WACKER’s management and workforce to prevent dismantlement were successful, and the plant’s facilities gradually went back into operation. It was not until 1953 that the Allies relinquished control over WACKER as part of their decartelization program, returning the company to its original owners.

Resistance to destruction of the plant

In the final days of the war, accountant Jakob Scheipel, senior factory foreman Ludwig Schön and foreman Josef Stegmair were sentenced to death in a drum-head trial and shot in the factory yard because they had attempted to prevent the National Socialists from destroying the plant.

“Foreign workers” replace around a third of the core workforce called up for military service

A dark chapter for which WACKER takes responsibility: in 2000, WACKER became part of the “Foundation for Remembrance, Responsibility and the Future,” which made compensation payments to victims of forced labor and to foreign workers.

-

1947

-

1945

-

1944

The outbreak of World War II

Following the outbreak of the second World War, nearly all WACKER operations were deemed important for the war effort. This meant that production of base chemicals such as acetylaldehyde, acetic acid and chlorinated solvents continued unabated. Especially important during this time was the manufacture of high-quality metal alloys such as ferrochrome or ferrosilicon at WACKER’s former plants in Mückenberg and Tschechnitz.

Patent application for the suspension polymerization process for PVC

Dr. Herbert Berg developed the process for manufacturing PVC. From 1935 until the business field was sold in 2000, WACKER PVC, which was marketed under the VINNOL® brand, turned into a growth engine that financed the development of modern production lines such as silicones and hyperpure silicon.

Start of VINNAPAS® production

The managing director of the Consortium für elektrochemische Industrie, Willy O. Hermann, laid the foundation for today’s WACKER POLYMERS business division back in the 1920s. Together with his team, he developed a process for producing vinyl acetate from acetylene and acetic acid on an industrial scale. In 1928, vinyl acetate went into production, followed two years later by polyvinyl acetate. Over the years this would develop into the VINNAPAS®product line, which ranges from adhesives in the wood industry to binders for construction applications, plastics, paper grades and woven fabric.

-

1939

-

1935

-

1930

Production of intermediate and end products from acetic acid

This bestseller was in production for almost 100 years. Acetic anhydride is used for the manufacture of pharmaceuticals and crease-resistant textile fibers. Production stopped in 1997.

Company founder Alexander von Wacker, recently raised to the non-hereditary aristocracy, died at the age of 75.

* May 29, 1846

† April 6, 1922

WACKER shellac made from plastic

The first plastic made from acetylaldehyde produced in Burghausen contributed to the ever-increasing vogue of gramophone records at that time.

Founding of Alzwerke GmbH, construction and commissioning of the Alz Canal

The 16-kilometer Alz Canal that joins the Alz and Salzach rivers became WACKER’s lifeline. The tamed hydropower of the Alz River generated cheap, sustainable electricity – and still does. The amount of electricity obtained per year is equivalent to the power consumed by a town with some 80,000 inhabitants.

-

1922

-

1918–22

Start of acetone production

With 450 employees, the factory began producing acetone from acetic acid in Burghausen in the middle of the First World War. Suddenly, acetone became important for the war effort: it was used to make synthetic rubber for sealing submarine batteries. This was the starting point on the trajectory to becoming an international chemical company.

Construction of the plant in Burghausen, Upper Bavaria

The first products manufactured in December 1916 were acetylaldehyde and acetic acid, which WACKER chemists developed by reacting acetylene (made from calcium carbide) with water. This entered the annals of the chemical industry as the 1st WACKER process for producing acetylaldehyde. These products were in the WACKER portfolio until 2012.

October 13, 1914

Establishment of Dr. Alexander Wacker, Gesellschaft für elektrochemische Industrie, AG

Having trained as a cloth dealer and salesman, Alexander Wacker had by this time already earned a reputation as a successful businessman, and together with Sigmund Schuckert, he had made Elektrizitäts AG (EAG) in Nuremberg into a leading business in the electricity industry.

A visionary – even at the age of 68. His new business model: to build an industrial plant, covering applications ranging from electrochemistry to organic chemistry.

-

1917

-

1916

-

1914