“System: Circuit” – Artwork Made of Silicone at Murnau City Hall

Nov 13, 2020 Read time: approx. MinutesMinute

An Unbeatable Combination

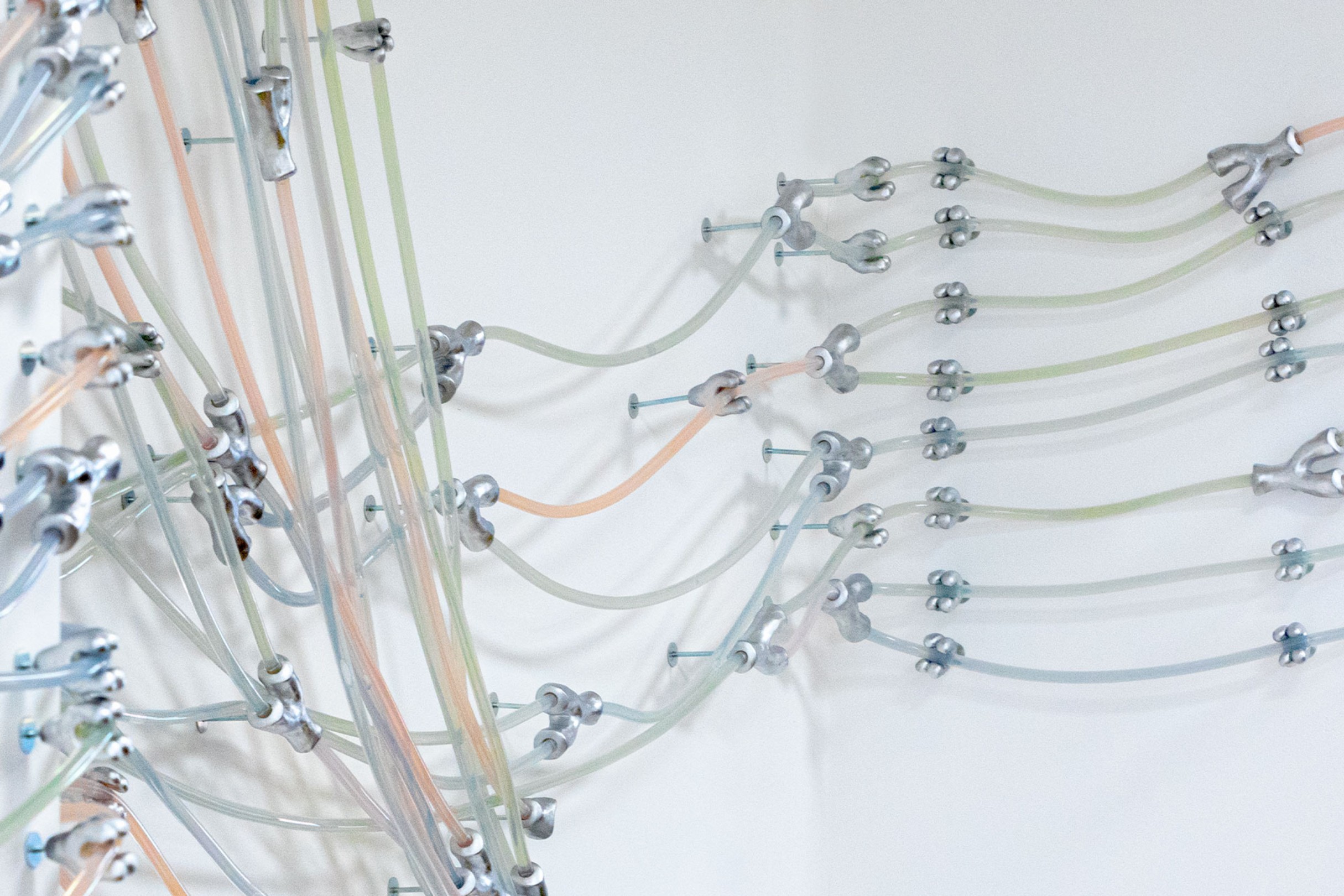

Creating works of art takes more than just creativity. Artists also have to find the right materials to make their ideas a reality. Thanks to two different silicones from WACKER, Lena Policzka was able to do just that for her art installation entitled “System: Circuit” at City Hall in Murnau, Germany.

Her installation “System: Circuit” has been hanging in the council chamber of Murnau City Hall since early September, and that has special meaning for artist Lena Policzka. Not just because she lives right around the corner in the village of Unterammergau, but because Murnau, a town of 12,000 people in Upper Bavaria, has left a major mark on art history – despite its small size. Painters Gabriele Münter and Wassily Kandinsky, who lived together as a couple for many years, worked there, as did other members of Der Blaue Reiter, or The Blue Rider, a movement prior to WWI that served as critical inspiration for Expressionism.

To this day, the citizens of Murnau feel a strong affinity for the fine arts, and so in 2019 they called for proposals for a redesign of the council chamber at City Hall – a competition that Policzka won. The 33-year-old artist did not limit herself to just decorating the walls, but instead devised a complete concept for the space.

“I felt strongly about using more than just individual chamber walls as my canvas – I wanted to tie in the whole space,” says Policzka, who creates installations and sculptures. Her idea was to create a diagram representing a living discussion – one that, in a metaphorical sense, tells a story about what goes on in the chamber. “I see the municipal council as a river delta fed by citizens’ concerns. I also liked the image of a mental switchboard – a communication network with neurons and synapses. Neural pathways take information and direct it to nerve cells where it’s bundled and analyzed, and ultimately used for making decisions,” she says.

The work also needed to incorporate aspects of the landscape, which, in Murnau, is dominated by the waters of Lake Staffelsee, the moorlands and mountain chains – a panorama that the town’s painters made famous as “The Blue Land.”

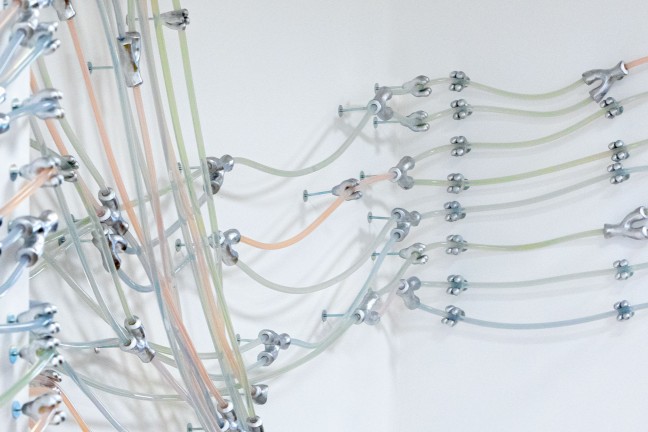

To make all of that a reality, the artist quickly realized that the best way for her to express her idea was to translate it into a tapestry of tubes and connectors filled with flowing colors. Her work contains several hundred of these nodes and brackets and roughly a kilometer of tubing.

The tubing was extruded from silicone rubber and filled with a silicone gel to which a pigment had also been added.

It’s important to know exactly what properties the customer needs. That’s the only way to pick the ideal silicone, so that we can then optimize the blend with the right additives.

Richard Heider, director of Application Technology, Silikon-Technik Siltec GmbH & Co. KG

The completed art installation in the council chamber of Murnau city hall is a metaphorical expression of the flow of information and lively dialogue that a democracy needs.

A Loop around the Room

The network runs along the walls of the entire chamber, encompassing its full perimeter. The entrance to the chamber serves as both the beginning and the end of this loop – the point, in other words, where citizens’ concerns enter the discussion and where decisions exit. But what materials would work for the installation? How do you make the most effective use of colors and shapes? What is actually doable? And how? “What I especially wanted was to give the impression of water flowing in the tubes. But at the same time, I also wanted to incorporate the colors of the landscape,” Policzka points out.

Gel, Not Liquid

Filling the tubes with real liquid was not an option, however: “Pigments break down in liquids. In the end, a restorer friend of mine suggested working with silicone gels,” she explains. Policzka turned to SILGEL® 612, a pourable, addition-curing, two-part RTV silicone rubber compound from WACKER. The major advantage of this silicone is that it – along with the pigments it contains – cures to form a crystal-clear material as soon as the starting materials have been mixed. Silicone is also UV resistant, which keeps it from aging or yellowing. For the artist, the tiny, entrapped air bubbles that manufacturers do their very best to prevent in industrial applications were perfect, creating the illusion of flowing water.

The abstract network flows in organic contours that can be reminiscent of a lot of things: sometimes a mountain chain, sometimes the cheerful play of water when you set the surface in motion, sometimes a huge neural network.

Lena Policzka, artist

Policzka used roughly one kilometer of silicone tubing and several hundred nodes in her installation.

While it did not take long to see that silicone gel was the ideal material, the search for suitable tubing turned out to be more difficult. “It needs to be stable over a long period of time, after all – and that’s not the case with PVC, which gets brittle after a while. The manufacturer could only guarantee a service life of five years, which wasn’t long enough,” she explains. A lengthy search took her once again to WACKER – or, more precisely, to Dr. Christian Anger, who directs an applications technology lab for WACKER SILICONES in Burghausen.

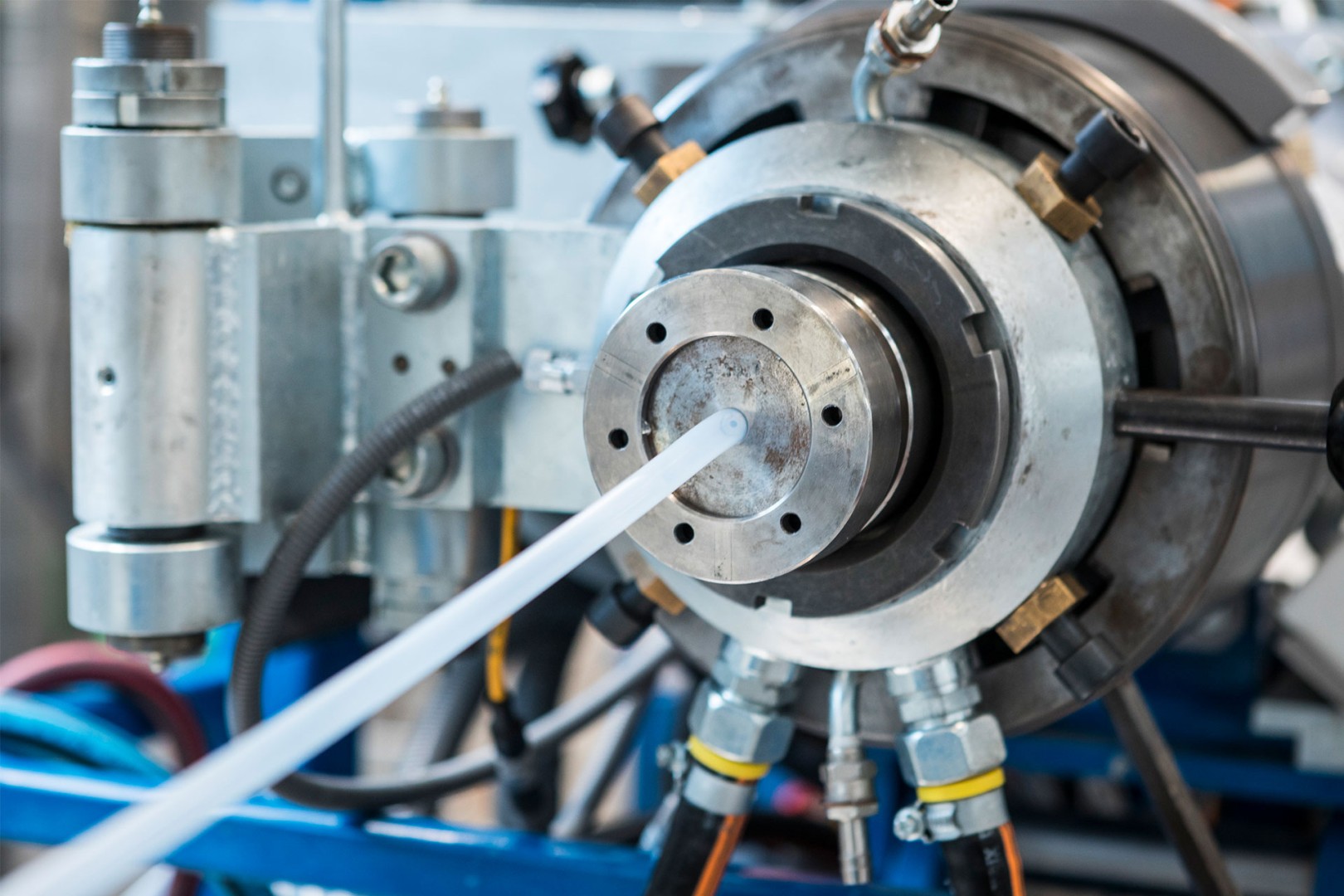

“It’s pretty unusual for someone to ask us to pick the right silicones for an art project,” the chemist recalls. “But it was also a welcome departure from our routine work,” he adds with a laugh. Anger normally works with silicones used in extrusion processes to make tubing for food-technology or medical applications such as urinary catheters or wound drainage systems.

SILTEC

Founded in the late 1970s in Weiler, Germany, Silikon-Technik Siltec GmbH & Co. KG (www.siltec.de) and its roughly 200 employees produce silicone components for the medical technology, pharmaceuticals, food, automotive, road construction, aviation, aerospace and other specialized industries. The company, which manufactures both molded and extruded parts, has its own compounding facilities and operates injection molding, extrusion, compression molding and transfer molding processes. In addition to standard products, its extrusion processes are also suitable for producing complex geometries, as well as coextruded and fabric-reinforced products.

Unique Requirements

He suggested Policzka try ELASTOSIL® R plus 4305 for her installation in the Murnau city council chamber. “Given what she needed, it didn’t take long to decide which material to use,” Anger says. “The tubes needed to be stable for a long time, highly transparent, colorless and odorless.” Because the company is happy to support artists, WACKER also donated the silicone rubber.

Once the right material had been found, however, another company had to be involved to turn the silicone into tubing. “We provided support there too. To put it in our industry jargon, we more or less helped set up a supply chain for that part of the project,” Anger explains with a grin. “There aren’t that many companies out there that have the flexibility to respond to customer requests like that and can take on such small projects.”

WACKER experts therefore turned to Silikon-Technik Siltec (www.siltec.de), a silicone compounder from the Allgäu region of Bavaria, bringing the company on board in February 2020. The two companies are connected through decades of partnership and collaboration. “We’re not just a WACKER customer – we’re regularly involved in development projects and are constantly talking with them in order to offer the best solutions we can,” says Richard Heider, director of Application Technology at Siltec. “We also manufacture highly customer-specific products – and what Lena Policzka needed certainly fit that profile.”

The experts at Siltec created their own formulation for the tubes, using WACKER silicone as the base material. “That’s why it’s important to know exactly what properties the customer needs,” he added. “It’s the only way to pick the ideal silicone so that we can then optimize the blend with the right additives.”

The same goes for the extruder parameters – pressure, temperature, speed, processing window – which have to be set just right for the subsequent extrusion step, because these will determine the ultimate product properties. “The biggest challenge for us was to take the desired artistic qualities and translate them into quantitative, technical parameters,” he recalls.

We also manufacture highly customer-specific products – and what Lena Policzka needed certainly fit that profile.

Richard Heider, director of Application Technology at Siltec

Exceptionally Transparent Material

Another important consideration: the various colors of the silicone gels needed to be as true as possible, which required exceptionally transparent tubing with no inclusions that would get in the way. “A really smooth surface was important to me too – so not one that’s a little sticky, like silicone surfaces often are,” Policzka says.

That was something else the Siltec experts could do: a special surface treatment makes the tubing feel smooth, to the point of attracting almost no dust. “It was incredibly exciting to work with WACKER and Siltec and express my artistic and aesthetic vision in technical terms. I’m extremely grateful for the wonderful advice that I got from both companies,” she adds.

“System: Circuit” has been in place at the Murnau city council chamber since September 9, 2020, where it serves as a visual representation of what goes on there: ideas and discussions move through the room, compromises are made, new suggestions are put forward or are rejected – until a consensus decision finally exits. A work of art, in other words, that basically expresses the soul of the space.

Mr. Dr. Christian Anger

Technical Support

Rubber Solutions, WACKER SILICONES

+49 8677 83-86172

christian.anger@wacker.com