The Battery Show North America 2024

WACKER Advances Silicones for Next Generation Thermal Gap Fillers and Adhesives

Ann Arbor, Oct 07, 2024

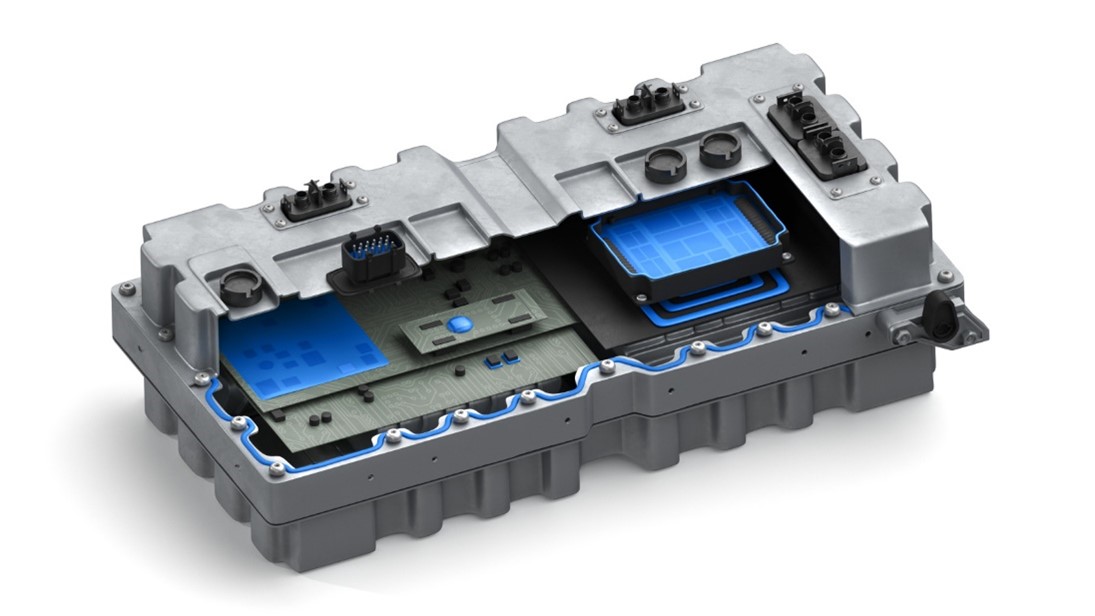

Wacker Chemical Corporation, the Ann Arbor-based subsidiary of Munich-based chemical company WACKER, will be presenting silicone products for battery technology and electromobility and showcasing technical expertise and capabilities for designing customized customer solutions at this year’s Battery Show North America. The focus will be on adhesives and silicone-based ceramifying coatings including WACKER’s ELASTOSIL® and SEMICOSIL® thermally conductive silicone products. They provide highly efficient and reliable thermal heat control in a wide array of applications and offer various viscosities, curing speeds, and thermal conductivities to expertly address the thermal heat management needs of virtually every industry demonstrating advances in thermal gap fillers and potting leading to long-range battery propulsion. WACKER products and solutions boost battery safety in electric vehicles by ensuring the reliable operation of battery cells and preventing fire from spreading in the event of thermal runaway in a cell. The Battery Show North America will be held in Huntington Place, Detroit, Michigan, from Oct. 7 to Oct. 10.

As battery technology continues to evolve toward a standard in the e-mobility space, WACKER’s team of technical experts offers a solution platform that is versatile, customer-led, and designed to meet the unique needs of OEMs and automotive component parts, and modules suppliers through discreet partnerships with engineers, R&D specialists, and technical managers to find optimal solutions that help customers maintain their strategic edge without compromising their competitive value propositions for battery, range, and power storage capabilities that are central to electric vehicles.

“With increasing battery power density storage capacities and voltage levels, thermal management is an area of critical concern for the safety of the OEMs end user. Silicone-based thermal interface materials (TIMs) play a pivotal role in effectively cooling batteries, even in extreme environmental conditions,” said Alex Shimazaki, automotive marketing manager, Wacker Chemical Corporation. “Our technical team possesses deep industry knowledge and experience partnering with customers to understand their unique needs and mobilizing our expertise in silicone products to address the diverse configurations and peripheral components inherent in the battery and electric vehicle sector.”

Optimizing a battery's performance, reliability, and safety relies heavily on maintaining a consistent temperature within a specific range. For instance, lithium-ion batteries perform at their best between 20 and 35 °C. To achieve this, the use of thermally conductive silicone is crucial for cooling the battery pack, dissipating internal heat, bonding the cells, and providing damping and vibration control. This versatile material offers solutions for ensuring the efficient and reliable operation of battery systems.

Silicone Solutions Extend EV Battery Life & Promote Safety

WACKER ELASTOSIL® and SEMICOSIL® are at the forefront of supporting the electrification of EV drivetrains with state-of-the-art silicone-based product solutions. The performance and safety of a battery pack are intricately tied to factors such as pack design, topology, cell architecture, and various other elements. Using silicones, WACKER’s solutions significantly enhance performance, functionality, and safety, while also extending the service life of EV batteries. Silicones such as elastomers and resins are the products of choice where high temperature resistance and permanent flexibility are top priorities.

WACKER’s thermally conductive gap filler and potting products are engineered to ensure bubble-free application. Despite their high filler content, WACKER’s solution-infused TIM materials demonstrate excellent flow properties enabled by low viscosity, achieved through minimal thixotropic or pseudoplastic behavior, thereby reducing the risk of air bubbles.

"We continue demonstrating that we can offer resource-efficient versions of silicone products and compounds formulated to meet customer specifications," said Daryl Faybrick, Business Development Manager, Automotive Electronics at Wacker Chemical Corporation.

Visit WACKER in Detroit at The Battery Show North America 2024, booth 5011, October 7-10.

Click below to learn more about the products and services that WACKER is showcasing.

Contact

Media Contact

Wacker Chemical Corporation

Media Relations & Information

James Barnes

Tel. +01 734-546-4951

Send message