Mar 01, 2019 Read time: approx. MinutesMinute

Dispersible polymer powders for biocide-free wall paints

With WACKER’s new NEXIVA® product range, interior wall paints can be manufactured in powder form without added biocides.

Most wall paints are produced using water-based binders or raw materials. When used in paints, however, water provides a favorable environment for microbes and bacteria. In order to kill these organisms, the paints are typically formulated with biocides to make them last longer. According to the German Paint and Printing Inks Industry Association, one in four buckets of paint will spoil unless preservatives are added. That translates to eleven million buckets per year, at a cost of €470 million. Using biocides is problematic, however: they can cause an allergic reaction in some people.

With NEXIVA®, WACKER has now developed a technology for producing biocide-free paints. At the 2019 European Coatings Show, the Group will be presenting a product line based on spray-dried polymeric binders suitable for producing interior wall paints in either liquid or powder form. Just like traditional binders in dispersion form, paint manufacturers can use NEXIVA® to create individual paint formulations.

Powder paints remain stable, even without the addition of preservatives. Water for redispersing the paints is not added until just prior to application, thus eliminating the need for adding biocides during production. Thanks to the polymers, the paint adheres well and has good spreading properties. In addition, paints are easier to transport and store when they are in powder form, as they weigh less, for instance, and can be packaged differently from liquid paints. Unlike traditional wall paints, powdered versions do not freeze in the cold, nor do they thicken when exposed to heat.

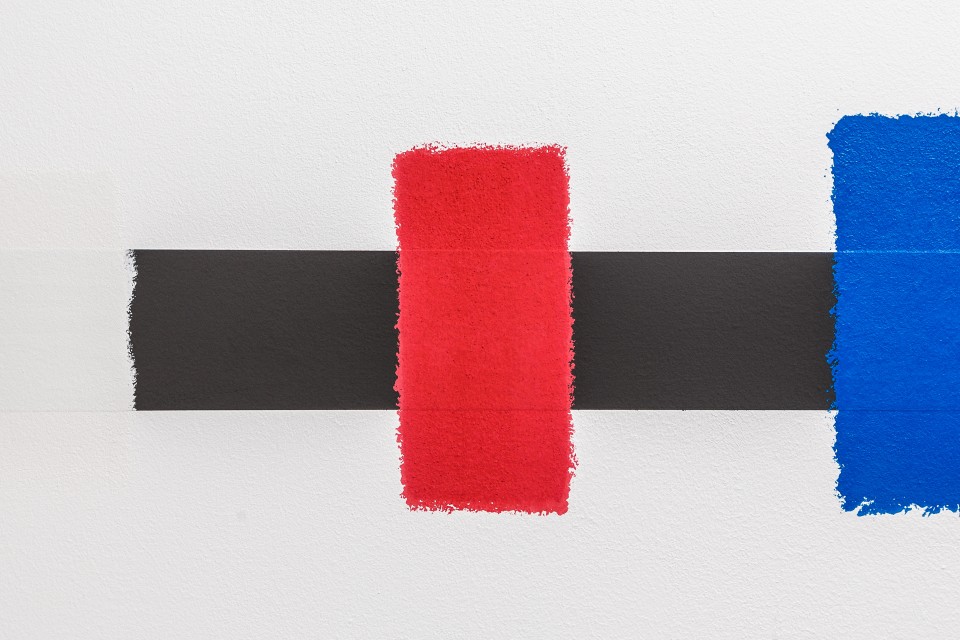

Formulation of NEXIVA® based powder paint and red pigments.