Press Photos

Please note our terms of use governing the use of press images. By downloading images from our media database, you agree to these terms of use:

Press images may only be used for press purposes (print, electronic media, online) and may not be edited. Indicating the picture credits (source: Wacker Chemie AG) is obligatory. Images deleted from the media database may no longer be used in future. If a press image is used, please provide us with a copy or link. In other respects, the following copyright information shall apply: www.wacker.com/disclaimer

Category

Reset perimeterVINNOL® E 18/38

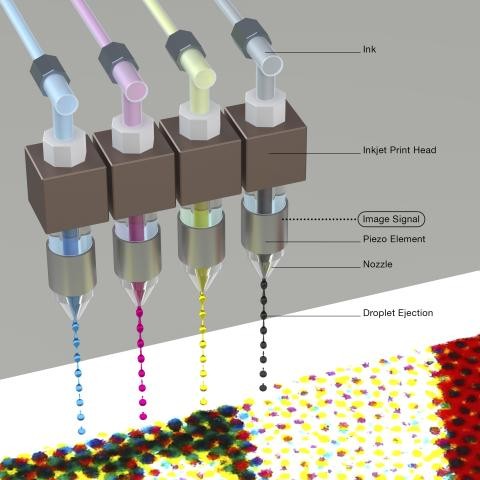

The low-viscosity binder VINNOL® E 18/38 ensures excellent droplet formation in ink-jet inks with high resolution and brilliant colors even at high print speed. VINNOL® E 18/38 adheres extremely well to numerous substrates, making it ideal for printing on cables, packaging or large-scale advertising banners

Order photoVINNAPAS® 760 ED

Outdoor weathering tests: The new VINNAPAS® 760 ED dispersion is ideal for flexible two-component sealing slurries for creating permanent, hard-wearing seals in damp rooms, such as kitchens and bathrooms, as well as for water pipes and sewers.

Order photoSILPURAN® 6760/50

SILPURAN®6760/50 is a self-adhesive liquid silicone rubber (LSR) which has a low-friction surface after curing. Tests show that the product’s coefficient of friction is 50 to 70 percent lower than that of standard LSRs with a comparable hardness. The Munich-based chemical company is premiering the new product at this year’s COMPAMED trade show.

Order photoLiquid Silicone Rubber SILPURAN® 6760/50

Self-adhesive SILPURAN® 6760/50 liquid silicone rubber was specifically developed for medical-technology and pharmaceutical applications. After curing, it has good mechanical properties and a low-friction surface.

Order photoSEMICOSIL® 811 silicone adhesive sealant

At the K 2016 International Trade Fair for Plastics and Rubber, WACKER will present the fast-curing SEMICOSIL® 811 silicone adhesive sealant. The product is designed for processing without using an oven and rapidly develops an adhesive bond to many substrates with only very low energy input. Electronics manufacturers can thereby flexibly adjust the processing of the new adhesive sealant to their manufacturing process, and so achieve short cycle times.

Order photo